Industrial Digitalization and Smart Manufacturing

Transforming Traditional Plants into Intelligent, Data-Driven Operations

At Olanab Consults, we help manufacturing and process industries transition from legacy operations to digitally enabled, data-driven, and intelligent systems. Our Industrial Digitalization & Smart Manufacturing services are designed to integrate cutting-edge technologies, automation tools, and analytics into your processes to boost productivity, enhance quality, improve maintenance strategies, and reduce operational costs.

Through a structured roadmap and practical implementation, we unlock the full potential of Industry 4.0 for your business—without overwhelming your team or infrastructure.

🎯 What Is Smart Manufacturing?

Smart manufacturing involves leveraging digital technologies such as sensors, industrial automation, cloud computing, IIoT, big data analytics, and artificial intelligence to create responsive, interconnected, and optimized production environments. It enables real-time decision-making, predictive maintenance, and continuous improvement based on live operational insights.

🏭 Our Approach

1. Digital Transformation Roadmap

Assessment of current operations and digital maturity

Identification of digitalization opportunities across process units

Roadmap development for short-, mid-, and long-term transformation

KPI definition and ROI projections

2. Smart Sensor Deployment & IIoT Integration

Installation of real-time monitoring devices for flow, temperature, pressure, vibration, etc.

Connection to IIoT platforms for centralized data capture

Cloud and edge computing setup for remote monitoring and diagnostics

Integration with SCADA/DCS and PLC systems

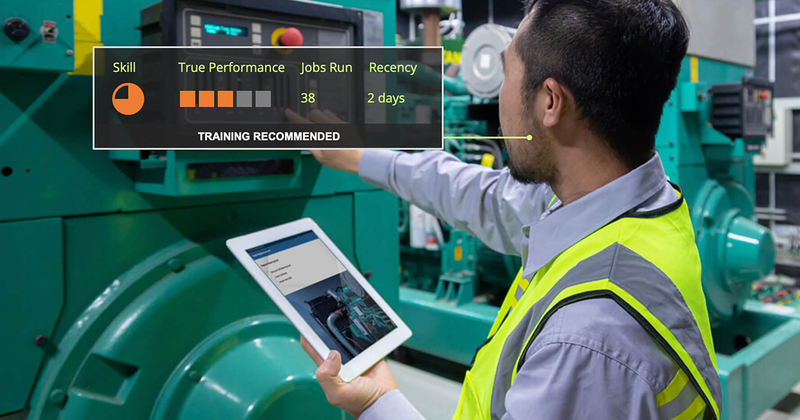

3. Predictive Maintenance & Asset Management

Implementation of sensor-based condition monitoring

Vibration, temperature, and acoustic diagnostics for rotating and static equipment

Machine learning models to predict failure and reduce unplanned downtime

Integration with CMMS/EAM systems

4. Advanced Process Control & Automation

PID tuning, feedback/feedforward control systems

SCADA and HMI design and programming

Batch process automation

Interlocks, alarms, and failsafe logic development

5. Real-Time Performance Monitoring & Analytics

Dashboards for OEE, energy consumption, downtime tracking

Digital KPIs accessible via web or mobile

Root cause analysis through historical trend review

Data integration from multiple systems (ERP, MES, LIMS)

6. Digital Twin & Process Simulation

Creation of a virtual replica of the physical process

Simulation of operational scenarios for planning and training

Testing of optimization strategies without disrupting actual operations

7. Workforce Digital Training & Change Management

Operator training in digital systems and smart devices

Skill-building for maintenance and production personnel

Workshops on Industry 4.0 adoption and culture shift

🔧 Industries We Support

Manufacturing (FMCG, Plastics, Engineering)

Oil & Gas / Petrochemicals

Power & Utilities

Food & Beverage

Pharmaceutical & Life Sciences

Water Treatment & Packaging

📊 Key Outcomes for Your Business

✅ Real-Time Data Visibility and Decision Support

✅ Reduced Downtime Through Predictive Maintenance

✅ Improved Quality Control and Batch Consistency

✅ Increased OEE and Line Throughput

✅ Reduced Energy and Utility Waste

✅ Seamless Regulatory and Compliance Monitoring

✅ Future-Readiness for Smart Factory Ecosystems

🔍 Case Highlights

Deployed a sensor-driven monitoring system for a beverage production line, resulting in 25% reduction in downtime and 15% increase in OEE.

Designed a digital dashboard for real-time KPI tracking across three production lines in a food processing facility.

🧰 Technologies & Platforms We Work With

Siemens, Rockwell, Schneider PLCs

Wonderware, Ignition, WinCC SCADA

OPC-UA, MQTT, Modbus communication protocols

Azure IoT, AWS Industrial Cloud, Google Cloud

Power BI, Grafana, Tableau for dashboards

CMMS tools: Fiix, UpKeep, IBM Maximo

💼 How We Work

Digital Readiness Assessment

Tailored Technology Recommendations

Implementation, Integration & Commissioning

Team Training and Handover

Continuous Optimization and Support

📞 Start Your Smart Manufacturing Journey Today

Whether you’re starting small with sensor-based monitoring or aiming for full plant digitalization, Olanab Consults is your trusted partner for industrial innovation. Let’s build a smarter, safer, and more efficient factory—one digital solution at a time.