From The Diaries of 'Messy Affairs With Industrial Pumps'

All physical phenomena is transient in nature and so do rotating equipment follow the same principle. The difference between a good engineer and a great engineer is that - A good engineer thinks how a piece of equipment is meant to be running while a great engineer understands that transient events (unsteady state) occur before a rotating piece of machinery runs the way it is meant to be. For engineers, it is necessary to understand how transient events affect the operation of large Industrial machinery. This will at least ensure you wake up the next day to make a dollar another day! Because if you thought it wasn't necessary, chances are that you'd probably end up in the Boss's office for an early performance review when your machinery conks out.

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

What Does A Centrifugal Pump Goes Through ??

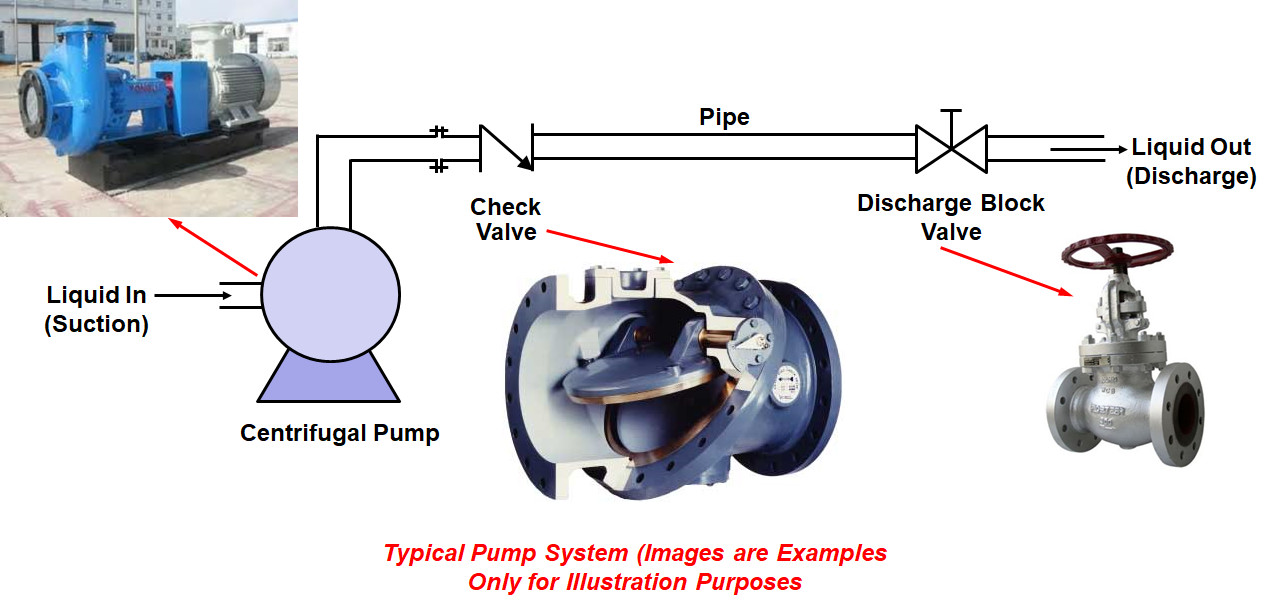

Pumps are the basic transporters of liquids in an Industrial Plant. They go through the three main stages - Startup, Running, Shutdown. It is during a startup and shutdown, rotating machinery go through an arduous journey of mechanical stress and strain for a while before being able to pump liquids steadily.

The above image is a simple construction of a pump system. It consists of a centrifugal pump with a suction pipe, a check valve that allows liquid to flow in only one direction and a discharge block valve to shut off the flow through the pipe. Pump systems are equipped with controllers that detect whether flow through the piping is blocked and instruct the pump to shutdown. Any abrupt shutdown means you can be sure of the chances that the pump is on its way to becoming damaged.

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

What is Liquid Hammer and Why is it a Nightmare!!

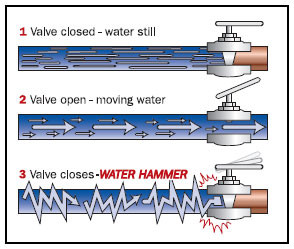

A liquid hammer can be simply defined as - Any rapid change in liquid flow conditions in a pipe that causes very high pressures and even reversal of flow. It's a phenomena where the flowing liquid in a pipe smashes itself against the pipe walls and valve fittings that the effects manifest visibly as vibrations and physical damage.

Vibrations are bad!! because pipes are placed on supports which also feel the stress and result in pipes bursting, support structures getting damaged and piping joints starting to leak. When pump systems carrying toxic liquids fail spectacularly due to a liquid hammer, its a recipe for potential human casualty as well (and probably the next script for an upcoming Hollywood Director who's aiming for an Academy Nomination!!).

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Causes of Liquid Hammer

- Pump Trip - Remember how you swung in your seat when you hit the car brakes all of a sudden!! Your body was still moving at the speed of the car until the brakes stopped the moving car. Similarly, when a centrifugal pump stops abruptly, the flowing liquid in the pipe also tries to come to a halt. But!! in doing so, the liquid mass slushes back an forth in the pipe, smashing against the walls and fittings. The larger the flow capacity, the larger is the liquid hammer effect and the quicker is the pipe rupturing.

- Discharge Block Valve Closing Abruptly - This is akin to a door closing all of a sudden on your face to end up with a broken nose!! Similarly when the discharge block valve closes abruptly for any number of reasons, the flowing liquid would smash itself against the face of the block valve. Remember!! A moving liquid possesses kinetic energy and upon bringing it to rest at the face of the discharge block valve, the kinetic energy is converted into pressure energy. This effect manifests itself as a pressure rise inside the pipe that can exceed the design pressure and cause the pipe to burst at the welded joints.

- Cavitation - Cavitation is a phenomena where due to liquid pressure dropping below its vapour pressure, bubbles start to form and coalesce. When the pump trips, the pressure in the piping can fall to a level that the liquid vaporizes, creating a vapour cavity. This causes the liquid to flow backwards carrying a collapsing cavity as it approaches the closed check valve or stopped pump only to collide and damage the pump parts.

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Centrifugal Pump Behaviour During a Trip Situation

Liquid Hammer is vast topic to deal with and in the interest of keeping this article brief, the Author chooses to describe one of the ways a liquid hammer can be avoided - i.e., By Controlling the shutdown behaviour of the centrifugal pump.

Pumps can trip due to power failure, mechanical failure, human error to name of few. Theoretically, a pump that is running at a certain speed can be assumed to reach a standstill in no time! However practically this is never possible and depending on the pump size and capacity, the pump takes its own sweet time to reach a state of rest. When a pump shuts down instantaneously, it produces the worst effects of the liquid hammer. So the idea to avoid a liquid hammer 'Is to slow down the rate at which a pump decelerates'. The slower a pump decelerates, the higher are the chances of avoiding a liquid hammer.

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

What does a Engineer Do to Slow down a Pump??

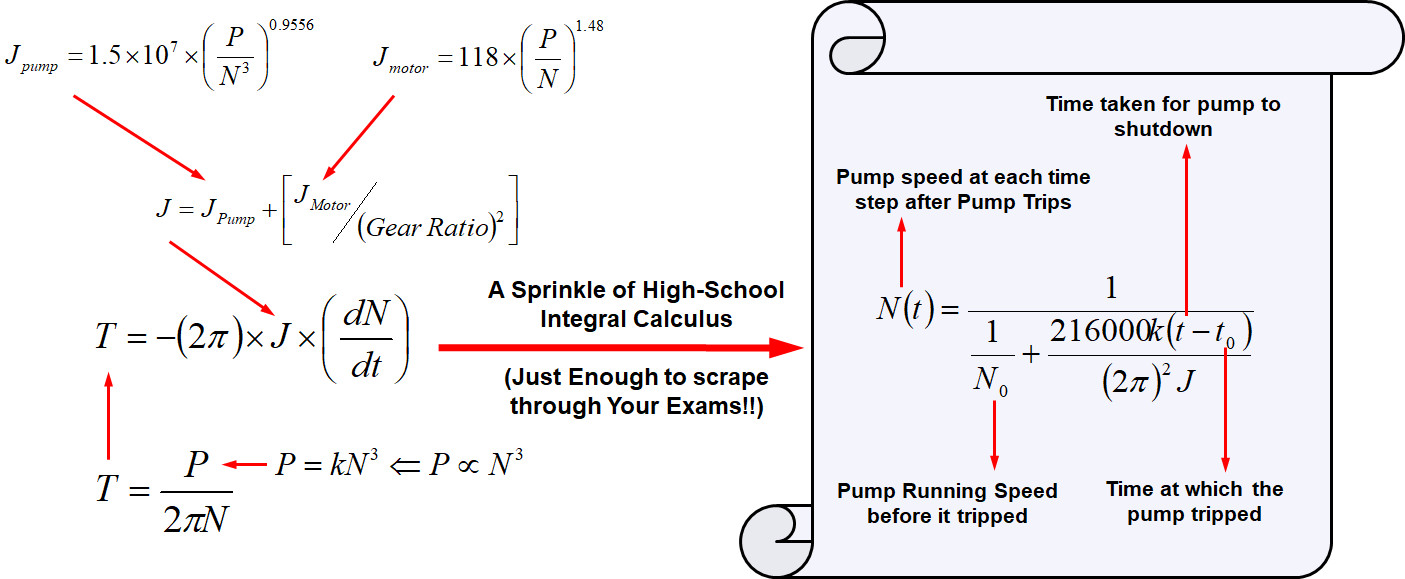

Engineers don't stop at sizing a pump for an application. They take the time off to estimate the time required for a pump to shutdown. To make a simplistic analysis that is free of any external forces acting on the pump impeller, the kind of data that a Chemical or Mechanical Engineer gathers to estimate the pump speed's decay rate (dN/dt) is the total inertia of the system ('J' expressed in kg.m2), Torque ('T' expressed in N.m), pump speed ('N' expressed in 'revolutions/min' or 'rpm'). All these terms are correlated with each other as shown below to derive an algebraic expression (SI system of units) with which the time taken for a pump to shutdown can be estimated.

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

A Simple Case Study

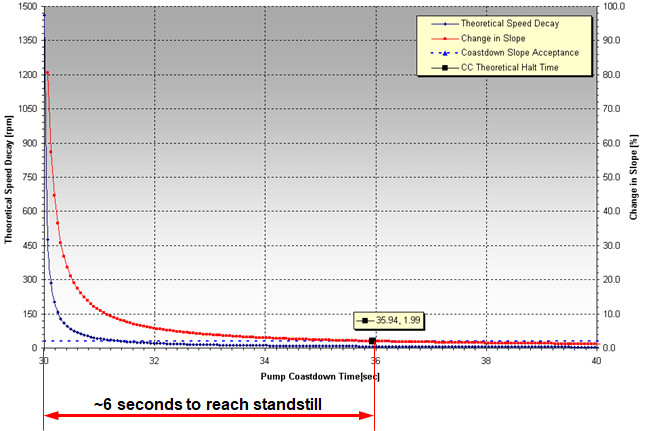

To demonstrate how the expression in the blue scroll is used, consider the hypothetical situation with hypothetical data where you were having a Burger during your break, and 30 seconds after you started chomping it down, a 250 kW pump running at 1460 rpm with an inertia of ~11 kg.m2 tripped due to a power failure. Using a simple tool like MS-Excel and the above expression, a graph can be plotted to estimate the time taken for the pump speed to reach a standstill.

Inferences from the above graph,

- From the moment the power tripped (i.e., 30 seconds from the time you had your burger), the pump took about 6 seconds to reach standstill. As a word of caution, it is to be noted that the blue line in the above graph is asymptotic i.e., the red line touches the X-axis (pump coast down time) at infinity.

- When a pump shuts down, the speed quickly drops exponentially in the initial stages. i.e., Along with torque decaying, momentum also decays followed by the forces of gravity doing the rest to stop the pump impeller from rotating.

- Higher the inertia, the longer it takes for the pump to slow down.

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Note: Pumps shutdown times are also influenced by the fluid resistance, dynamic imbalance, misalignment between shafts, leakage and improper lubrication, skewed bearings, radial or axial rubbing, temperature effects, transfer of system stresses, resonance effect to name a few and therefore in reality, shutdown times can be lower than estimated by the above method.

What Next??

With the pump shutdown time estimated, Engineers would use these numbers to conduct further studies called "Pipeline Surge Analysis" to determine if a pipe/pipeline operating pressures exceed its design pressure. If the pressure rise caused by the liquid hammer is higher than the design pressure of the pipeline, engineers embark on a pipe/pipeline saving mission whereby one or more of the following remedial measures are chosen

- Thicker pipes/pipelines are chosen to withstand the pressure rise - Increases CAPEX

- Reduce the Pumping Flow Rates - Check with your buyer whose buying the stuff that's reaching him through the pipeline (He might not be happy if there is less production!!)

- Install a Pump Flywheel to Increase the time taken for the pump to shutdown

- Install a Non-Slam Check Valve at the Pump Discharge that's closed by a spring. These valves don't rely on flow reversal or forces of gravity to close. Pressure spikes are lower compared to a traditional swing valve.

- Install Surge Tanks - Mostly used only for pumps transporting non-toxic fluids, e.g., Water

Equipment Images Courtesy and References: [1], [2], [3], [4], [5], [6], [7]

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

About the Author

Vijay Sarathy holds a Master’s Degree in Chemical Engineering from Birla Institute of Technology & Science (BITS), Pilani, India and is a Chartered Engineer from the Institution of Chemical Engineers, UK. His expertise over 16 years of professional experience covers Front End Engineering, Process Dynamic Simulation and Subsea/Onshore pipeline flow assurance in the Oil and Gas industry. Vijay has worked as an Upstream Process Engineer with major conglomerates of General Electric, ENI Saipem and Shell.