How Food Quality Inconsistency can Lead to Consumer Scrutiny

One of the perks of being in the boarding house in secondary school was the "provisions"; that is, the beverages, milk, biscuits, breakfast cereals, etc that we were allowed to have in our lockers. Those precious food products saved us in times when the food from the refectory didn't meet our specifications in terms of taste or quantity. Boarders in the house, true or false? 😅

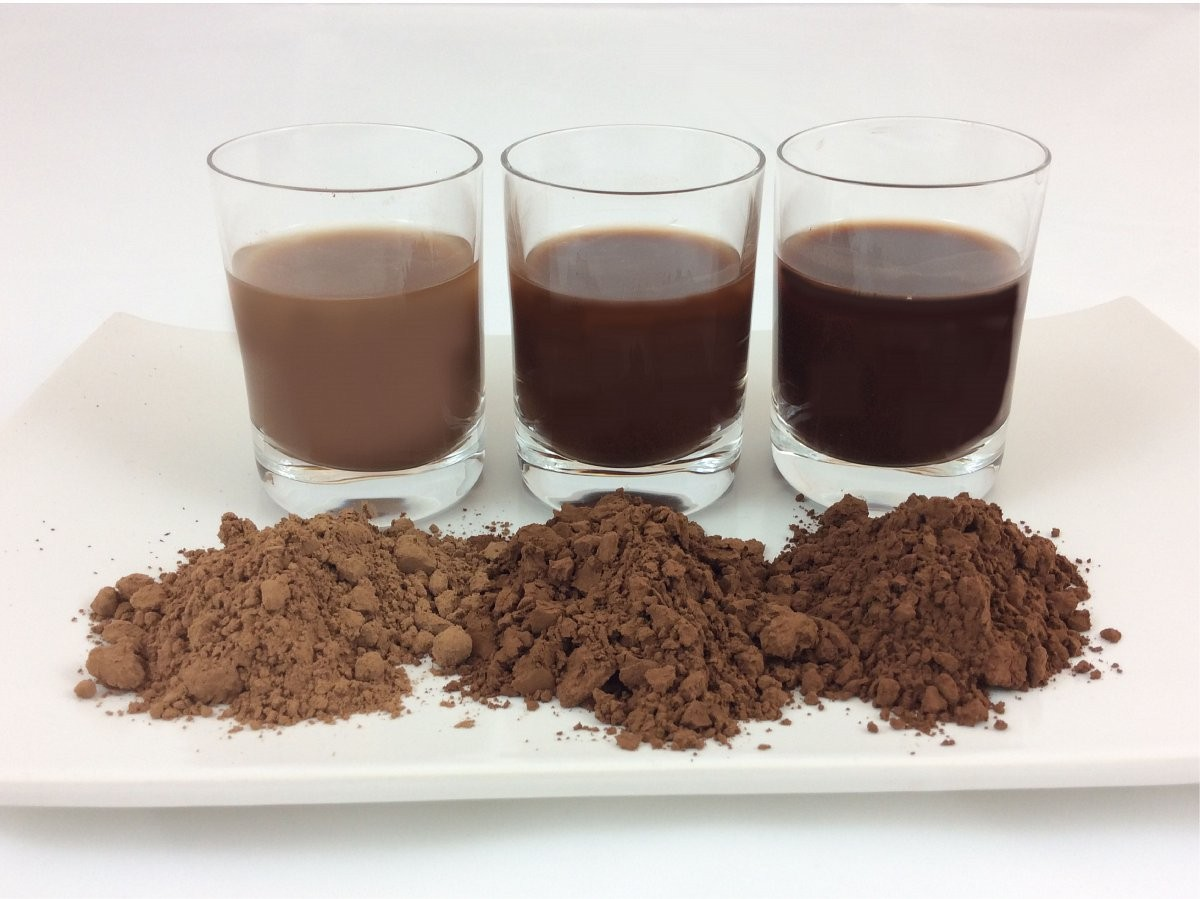

On one of such days when the food served at the refectory didn't meet my spec, I remember going back to the hostel to treat myself to some biscuit flakes. On opening a tin of my favourite chocolate beverage powder, I was met with a product with different physical properties. The colour looked lighter than the usual dark brown colour, the texture was gritty against the usual fine powder and to make matters worst, the taste was different in a bad way! That incident made me have doubts about the brand. You can call this consumer scrutiny.

Click Here to Join the Over 2700 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 2700 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Image Credit: The Washington Post

Have you ever had doubts about consuming a food product from a brand that you have patronized severally just because you observed something "strange" or "unfamiliar" with the product?

If you're a loyal/regular customer or consumer of a particular food or beverage product, who like me, pays attention to details...then it's easy to observe even the slightest changes in product appearance, colour, taste, texture, aroma, as well as changes in packaging material or even coding patterns.

Click Here to Join the Over 2700 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 2700 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Image Credit: Global Organics

As a manufacturer, in as much as there are bound to be slight variations from one batch production to another, the variations should not be so wide apart or you may risk enabling counterfeiters to use your product as an easy target for food fraud which is not good for the business. Product inconsistencies may be interpreted by consumers negatively (as counterfeiting for example) and this can lead to loss of buyers due to apathy. For the food consumer, product quality to a large extent is tied to sensory perception.

Click Here to Join the Over 2700 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 2700 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Here are 3 pathways to product quality inconsistencies during food manufacturing operations and how to address them.

- Sourcing of raw materials: Variability in physical and chemical composition of raw materials, especially agricultural produce can lead to variations in the physical properties or taste profile of the finished product. Always ascertain the impact on physical and organoleptic properties of your finished product whenever a change/substitution is made from one raw material vendor to another and from one batch/lot to another.

- Recipe weighing: As simple as this may seem, the overall product outcome depends largely on accuracy of measurements of the bill of materials and ensuring that no material is omitted. Each material plays a technical role in the finished product, which could be colouring, flavouring, binding, sweetening, emulsifying, etc. Omissions, underweight and overweight measurements of raw materials and additives should be avoided. Ensure that weighing scales are functioning optimally and calibrated as at when due.

- Unit operation sequence/methodology: As much as possible, stick to the approved sequence of each unit operation. For example: If the approved sequence/methodology says mix/blend for 5 minutes, then 5 minutes must be maintained across shifts daily unless otherwise stated. Blending or mixing for prolonged time may result in changes in colour, appearance and textural properties.

Remember, word-of-mouth marketing is still very powerful. Satisfied consumers are not just buyers, they are also advertisers. Unsatisfied customers on the other hand, are the best demarketers.

Click Here to Join the Over 2700 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 2700 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

About the Author

Chidinma Ezinne Ochulor is a certified Food Technologist, a quality assurance professional with over 3 years' experience. She is a professional member of the Nigerian Institute of Food Science and Technology (NIFST). Reach her on LinkedIn, here.