How to Calculate Settle Out Conditions in a Centrifugal Gas Compressor

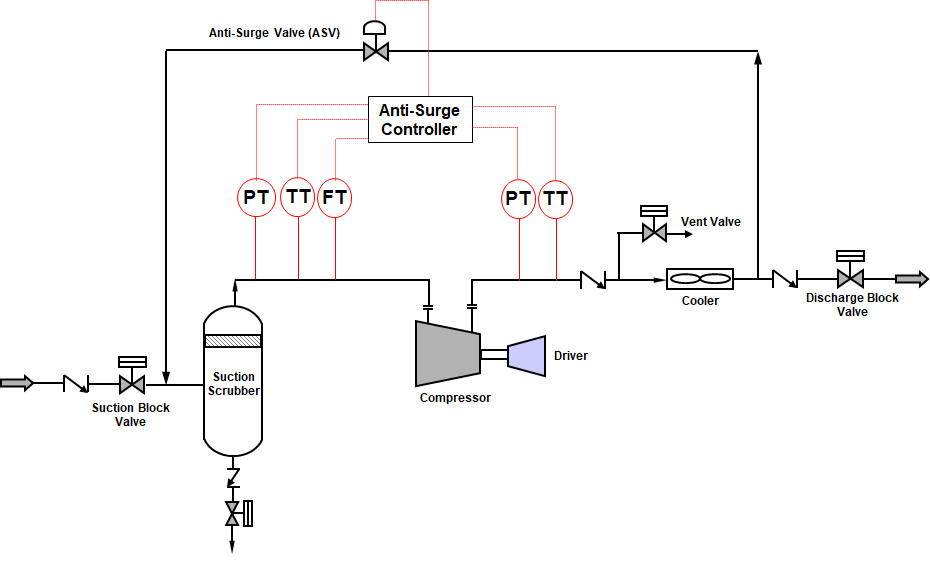

Compressor systems are used in gas re-injection systems, gas pipelines, gas processing plants, LNG facilities, and gas storage facilities. When these machines are shutdown, things happen inside them and it does matter to know because restarting these machines is not so simple as switching on an Apple iPhone. Before understanding what settle out conditions represent, it helps to understand what a simple single stage centrifugal gas compressor system looks like.

What are Settle Out Conditions

A gas compressor consists of a suction side with pipes and valves and a suction scrubber that removes any liquids before sending the gas to the compressor. Once the gas is compressed and cooled, it is discharged through the discharge side of the compressor via the discharge block valve. In the event the compressor is shutdown as a planned event, i.e., normal shutdown (NSD), the anti-surge valve is opened to recycle gas from the discharge back to the suction (thereby moving the operating point away from the surge line) and the compressor is tripped via the driver (electric motor or Gas turbine/Steam Turbine). In the case of an unplanned event, i.e., emergency shutdown such as power failure, the compressor trips first followed by the anti-surge valve opening. In doing so, the gas content in the suction side and discharge side mix.

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Therefore, settle out conditions is explained as the final pressure and temperature reached in the compressor piping and equipment volume when the compressor is shutdown.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Why are Settle Out Conditions Important for Design Engineers

The necessity to estimate settle out conditions are as follows,

- Settle Out Pressure determines the design pressure of the suction scrubber and suction piping.

- The suction scrubber is fitted with a pressure safety valve (PSV) whose set point (i.e., the pressure at which the PSV opens) is decided by the settle out pressure.

- When the compressor reaches settle out conditions, process gas is locked inside the piping and equipment and grips the compressor rotor from rotating effectively when restarted. Hence gas is blown down to a flare, via the vent valve to reduce the pressure caused by the tightly packed gas.

- Settle Out conditions also aid in determining how much volume of gas and how long, it must be purged from the system to cause an effective re-start.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

How to Calculate Settle Out Conditions (i.e., Settle Out Pressure & Temperature)

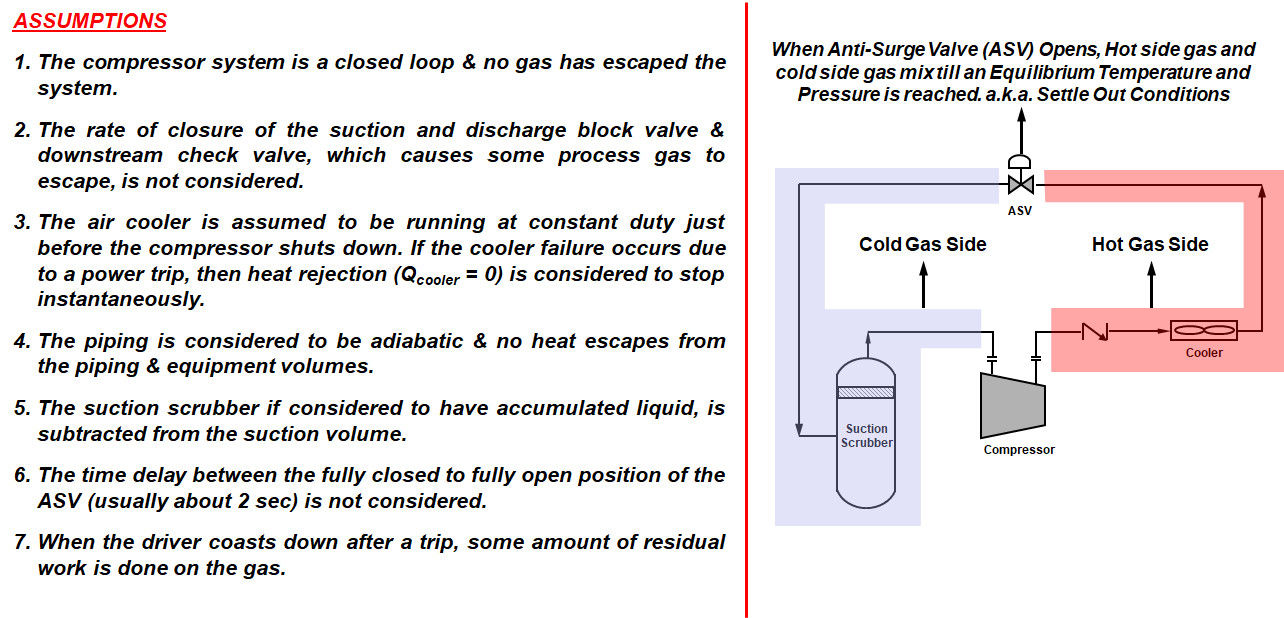

Although there are dime a dozen process simulations tools that can be used to conduct a transient study to determine settle out conditions, hand calculations based on first principles of thermodynamics can also be easily employed. In order to do so, the gas compressor system can be reduced with the assumptions as follows with the philosophy of using a lumped parameter model in which an energy balance is made across the total volume in the system including the compressor deceleration rate.

Performing an Energy Balance across the hot side gas and cold side gas,

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

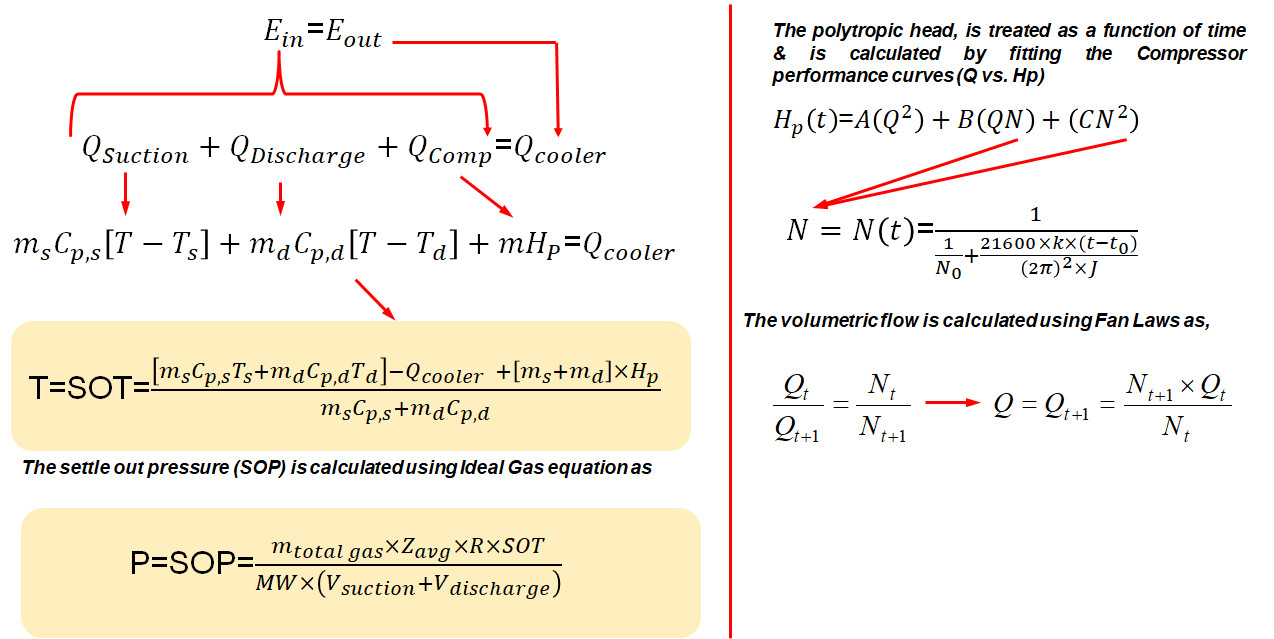

Case Study

Using arbitrary values, and a sample case of Normal Shutdown, a Centrifugal Compressor driven by an electric Motor (EM) is taken The configuration assumed is 15,000 Am3/h at 9,500 rpm with the suction side consisting of 50 m3 of piping and equipment volume, and 25 m3 on the discharge side. The gas temperature at the inlet is 55 deg.C and the discharge temperature is 135 deg.C. The suction scrubber is filled at 20% liquid level. The gas compressibility (Z) values at the suction and discharge is 0.98 and 0.95 respectively. The cooler duty is 1,500 kW while the compressor duty before shutdown is 1,000 kW. The gas MW is taken as 16 kg/kmol.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

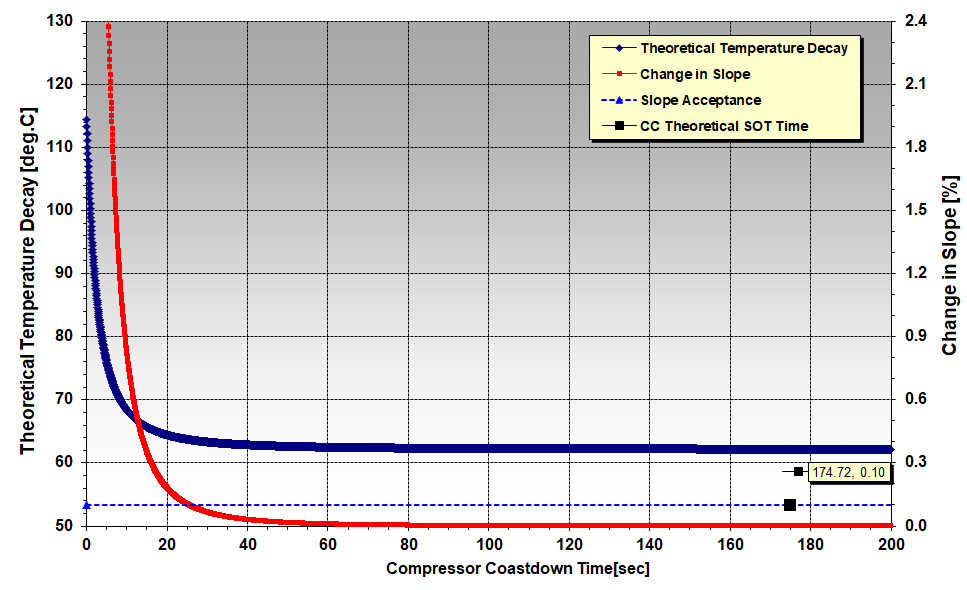

Based on the numbers used, the compressor comes to a halt in approximately 115 sec (~2 min) while the settle out temperature of 62 deg.C is arrived in 175 sec (~3 min). The settle out pressure (SOP) corresponding to the SOT of 62 deg.C is 2.15 bar(a). A plot of the compressor coast down trend and the settle out temperature is shown below.

Notes

Compressor shutdown times are also influenced by the fluid resistance, dynamic imbalance, misalignment between shafts, leakage and improper lubrication, skewed bearings, radial or axial rubbing, temperature effects, transfer of system stresses, resonance effect to name a few and therefore in reality, shutdown times can be lower than estimated by the above method.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

About the Author

Vijay Sarathy holds a Master’s Degree in Chemical Engineering from Birla Institute of Technology & Science (BITS), Pilani, India and is a Chartered Engineer from the Institution of Chemical Engineers, UK. His expertise over 16 years of professional experience covers Front End Engineering, Process Dynamic Simulation and Subsea/Onshore pipeline flow assurance in the Oil and Gas industry. Vijay has worked as an Upstream Process Engineer with major conglomerates of General Electric, ENI Saipem and Shell.