How to Transition from Standalone ISO Systems to an Integrated Management System

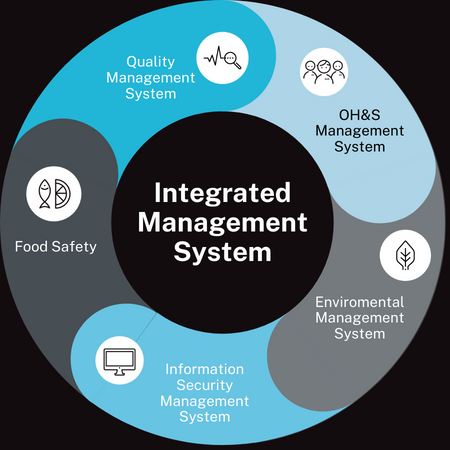

Organizations across industries often maintain separate management systems for quality (ISO 9001), environment (ISO 14001), and occupational health & safety (ISO 45001). Each standard specifies requirements for its domain – for example, ISO 9001 emphasizes consistent product/service quality and customer satisfaction, ISO 14001 focuses on minimizing environmental impact, and ISO 45001 seeks to prevent workplace injuries. Traditionally these systems operate in silos, with separate documents, audits, and objectives. An Integrated Management System (IMS) unifies these into one coherent framework.

By combining QMS, EMS and OHSMS (and potentially others) under the same structure, an IMS aligns policies and objectives, streamlines processes, and reduces duplication. In practice, this means one IMS manual and audit can satisfy multiple standards, rather than separate parallel systems.

The ISO organization itself has harmonized standard formats (Annex SL structure) so that clauses (e.g. Context, Leadership, Planning, Support, Operation, Performance, Improvement) are common across ISO 9001, 14001 and 45001. This shared high-level structure makes integration practical and efficient.

Benefits of an Integrated Management System

Integrating ISO 9001, 14001 and 45001 into one IMS yields multiple advantages by treating quality, environmental and safety requirements in a unified way. Key benefits include:

- Greater efficiency and cost savings

By eliminating duplicate processes and documents, organizations save time and resources. For example, shared procedures for document control, training and auditing mean less administration. One integrated audit can replace three separate audits, reducing audit days and fees. Consolidated training and combined objectives cut administrative overhead and waste.

- Improved compliance and risk management

An IMS provides a holistic view of risks and legal requirements. Integrated risk assessments identify hazards that span quality, environmental and safety domains. The organization can then address them with unified controls. Compliance tracking is simpler when one system covers all applicable regulations.

- Streamlined decision-making and reporting

Top management sees one set of metrics for an integrated system, facilitating clearer understanding of performance across areas. Integrated management reviews replace separate reviews, giving leaders a comprehensive view and enabling more agile decisions. Policies and objectives are unified, so all functions move toward common goals (e.g. customer satisfaction, environmental stewardship, worker safety).

- Enhanced organizational culture and stakeholder confidence

An IMS demonstrates a commitment to quality, environment and safety in a coordinated way. This can improve customer, employee and regulator confidence. For instance, addressing multiple stakeholder concerns together (product quality, eco-responsibility, worker well-being) leads to higher overall satisfaction. Cross-functional collaboration increases as silos break down, fostering a culture of integrated thinking.

- Scalability and easier addition of new standards

Because ISO management standards now share a common core structure (Annex SL), adding another standard (like ISO 50001 or ISO 27001) is simpler once an IMS is in place. The organization can grow its system without reinventing the wheel each time. Integrated documentation and processes provide a solid base for continuous improvement and future certifications.

Click Here to Download Readymade ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, HACCP, Food Safety & Integrated Management Systems (IMS) Templates.

Step-by-Step Guide to Integrating ISO Standards

Creating an IMS should follow a deliberate plan. A useful approach is to mirror the Plan-Do-Check-Act (PDCA) cycle that underpins ISO management systems:

- Plan Phase – Leadership, Scope and Assessment

Secure top management commitment and define the scope of the IMS. Management must set an integrated policy and objectives that address quality, environmental and safety goals together. Early on, engage stakeholders (employees, suppliers, regulators) to explain the IMS benefits and gain buy-in. Then conduct a gap analysis: review existing QMS, EMS, OHSMS documentation and operations against the combined requirements of ISO 9001, 14001 and 45001. Identify overlaps, redundancies and missing elements. Also inventory legal and regulatory obligations across domains.

- Best practice: Use the ISO high-level structure (Annex SL) as your framework. Group common clauses (Context, Leadership, Support, Performance, Improvement) into unified processes. For example, instead of separate context analyses for each standard, perform one contextual analysis of the organization’s environment and interested parties. Similarly, draft one IMS manual or combined policy covering all three standards, rather than three independent manuals.

- Resources: Assign an IMS project team with representatives from quality, EHS and other relevant functions. Allocate time and budget for initial analysis and training.

- Plan Phase – Integrated Objectives and Documentation

Based on the gap analysis, define integrated objectives and policies. Develop a single Quality-Environment-Safety policy statement that reflects commitment to all ISO requirements. Identify shared processes (e.g. training, document control) and unique ones. Where procedures overlap (such as management review, audits), plan to merge them. For example, use one internal audit program that covers requirements of all three standards concurrently.Prepare new or revised documentation: an IMS manual or online portal that maps each ISO clause to integrated processes.

Use unified procedures for document control, records, corrective action, and audits. Ensure clarity: even though the manual is integrated, it should be well-structured so auditors and staff can see how each ISO requirement is met. Tools like process flowcharts or cross-reference tables can help visualize linkages.

- Do Phase – Implementation and Training

Roll out the integrated processes across the organization. Provide training and awareness so that all employees understand the IMS structure and their roles within it. Emphasize how common procedures now fulfill multiple ISO requirements. For instance, a single training session on risk management might cover both quality and environmental risks. Use consistent training materials for shared topics to reinforce unified understanding.

Implement the integrated risk management process: identify risks and opportunities for the IMS as a whole (combining quality, EHS, etc.) and plan controls. Ensure that resources (people, infrastructure) are allocated to support all areas of the IMS. Update any management software or tools to reflect the new integrated structure.

- Check Phase – Integrated Audit and Monitoring

Transition from separate audits to integrated audits. Internal and external audits should cover all standards in one audit cycle. This requires using an audit checklist that includes ISO 9001, 14001, 45001 clauses. Record and address nonconformities from an IMS perspective – one corrective action process can serve all systems.

Monitor performance with combined metrics and indicators. Define KPIs that reflect IMS objectives: for example, an IMS dashboard might track customer complaints, number of safety incidents, and environmental incidents together. Reporting can then aggregate improvements across areas, showing overall system health.

- Act Phase – Management Review and Continual Improvement

Conduct one integrated management review instead of separate reviews. Top management should review IMS performance across all domains, considering audit results, achievement of objectives, and changing circumstances. This review drives decisions on improvement actions.

Use the PDCA cycle continuously: update the IMS as business changes. Encourage feedback from all levels (e.g. cross-functional teams) for improvements. Over time, the organization will refine processes to make the IMS more mature and effective.

Click Here to Download Readymade ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, HACCP, Food Safety & Integrated Management Systems (IMS) Templates.

Key Considerations and Best Practices

- Leverage the High-Level Structure (Annex SL): Use the shared clause structure to harmonize processes under each clause. Draft documentation to meet requirements across all standards.

- Unified Policies and Objectives: Develop one policy statement encompassing quality, environmental, and safety commitments. Set integrated objectives to prevent siloed goals.

- Clarify Roles and Responsibilities: Ensure that roles understand their part in the IMS. Define clear responsibilities for shared processes.

- Communication and Training: Communicate early and often about IMS changes. Provide cross-training for unified understanding.

- Phased Implementation (if needed): Roll out integration in phases if needed. Begin with common standards and expand gradually.

- Process Orientation: Structure the IMS around core business processes and map each to applicable ISO requirements.

- Use of Standardized Templates and Tools: Maintain clarity and avoid duplication in documentation.

- Top Management Engagement: Leadership should actively support and review IMS performance.

- Alignment with Business Strategy: Ensure the IMS supports strategic goals and evolves with business changes.

Tools, Technologies, and Frameworks Supporting IMS Integration

- Annex SL (High-Level Structure): Foundation for aligning multiple ISO standards.

- PAS 99 (Specification for IMS): Guidance document for creating and maintaining an IMS.

- Audit Guidance (ISO 19011): Provides principles and guidance for integrated auditing.

- IMS and EHSQ Software Platforms: Centralized systems for managing all aspects of an IMS.

- Document Management Systems: Digital systems for document control.

- Risk Management and Compliance Tools: Help manage integrated risks and compliance.

- Continuous Improvement Frameworks: Enable ongoing improvement of the IMS.

- Training and Communication Tools: Support knowledge sharing and IMS awareness.

Common Challenges and How to Overcome Them

- Resistance to Change: Involve staff early and secure leadership support.

- Complexity and Scope Creep: Keep documentation simple and scope manageable.

- Conflicting Objectives: Use integrated risk assessments to balance goals.

- Maintaining Expertise: Provide cross-training and consider external support.

- Audit Coordination: Plan audits carefully and use multi-skilled teams.

- Documentation Overload: Focus on minimum necessary documentation and eliminate redundancy.

- Regulatory Alignment: Maintain a unified compliance register.

- Overlooking Culture: Promote cross-functional collaboration and unified values.

Click Here to Download Readymade ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, HACCP, Food Safety & Integrated Management Systems (IMS) Templates.

Case Examples and Use Cases

- Printing and Publishing: Utility cost savings and improved audit efficiency.

- Construction Industry: Integrated safety and environmental assessments.

- Information Technology: Cloud-based IMS platforms for centralized control.

- Manufacturing: Alignment of quality and sustainability goals.

Recommendations for Successful Implementation and Continuous Improvement

- Management Review Cadence: Regular reviews drive alignment and improvement.

- Integrated Internal Audits: Plan and conduct comprehensive audits.

- KPIs: Track integrated performance metrics.

- Continuous Improvement Culture: Encourage staff to suggest cross-functional improvements.

- Strategic Alignment: Ensure IMS supports evolving business priorities.

- Training and Competency: Maintain skills through ongoing learning.

- Data and Feedback Use: Leverage tools and stakeholder input for refinement.

- Certification and Benchmarking: Pursue integrated certification and external validation.

An Integrated Management System unifies quality, environmental and safety management into one framework. Transitioning from standalone systems requires careful planning, but the rewards in efficiency, compliance and performance are substantial. Following the steps and best practices outlined ensures a robust, scalable, and value-adding IMS.

Click HERE to download or any of the following documents:

Integrated Management Systems (IMS) Implementation

IATF 16949 Automotive Quality Management Implementation Kit

ISO/IEC 17025 Laboratory Management System Implementation Kit

HACCP Implementation Kit

ISO 9001 Quality Management Systems (QMS) Implementation

ISO 22000 Food Safety Management Systems (FSMS) Implementation

Food Safety Systems Certification (FSSC) 22000 v5 Implementation

ISO 14001 Environmental Management Systems (EMS) Implementation

ISO 45001 Occupational Health & Safety Management Systems (OH&SMS) Implementation

ISO 50001 Energy Management Systems (EnMS) Implementation

Industrial Health, Safety & Environmental Management (HSE) Kit

Process Manuals

SON Compliance Documentation Kit

NAFDAC Compliance Documentation Kit

QA/QC Documentation Kit

Equipment Maintenance Documentation Kit

Production Management Documentation Kit

Production, Quality Control / Equipment Maintenance Kit

Lean Six Sigma

Lean Management/Manufacturing

Six Sigma Kit

Supplier Quality and Compliance Management (SQCM) Kit

Risk Management