Implementing FMEA in Manufacturing Processes

What is FMEA and Why Is It Valuable?

Failure Modes and Effects Analysis (FMEA) is a structured, proactive method for finding and preventing potential problems in products or processes. In simple terms, teams ask “how might this go wrong?” at each step or component, and rate each failure’s impact, likelihood, and ease of detection. By focusing on the most serious risks, small manufacturers can catch hidden issues early, improving quality and avoiding costly defects or recalls. For example, FMEA “enhances product safety and quality by revealing hidden risks” that routine checks might miss. Industry experts note that FMEA is scalable to businesses of all sizes, so even a small shop with limited resources can use it to cut waste and increase reliability.

In practice, a good FMEA culture helps a team think ahead: it turns assumptions into checklists, catches errors before they cost time or money, and fosters continuous improvement.

Steps to Implement FMEA from Scratch

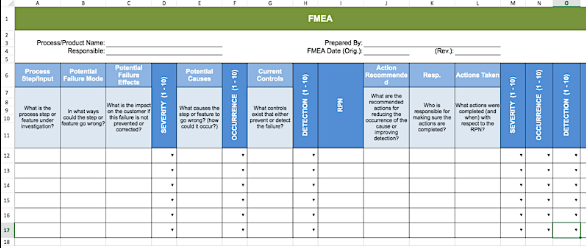

Getting started with FMEA involves a series of logical steps. It’s usually documented in a worksheet or spreadsheet so nothing is missed.

Figure: Example FMEA worksheet template.

Each row corresponds to a process step or component, with columns for potential failure modes, effects, causes, existing controls, and numeric ratings (severity, occurrence, detection) used to compute a Risk Priority Number (RPN). Using a structured template like this helps teams systematically capture each failure mode and plan corrective actions. For example, the RPN column in the template (computed as Severity × Occurrence × Detection) guides focus toward the highest-risk issues.

Click HERE for Industrial Automation, ISO Management Systems (ISO 9001, 45001, 14001, 50001, 22000, Integrated Management Systems etc.), Process Safety (HAZOP Study, LOPA, QRA, HIRA, SIS), Quality Management, Engineering, , Project Management, Lean Six Sigma & Process Improvement Self-paced Training Courses

- Define scope and objectives: Decide what you’re analyzing – a product, a process, or a sub-process – and set clear goals (e.g. “reduce defect rate on Machine A by 50%”). Gather a small cross-functional team (production, maintenance, quality, engineering, etc.) who know the work. The team should understand the process steps and have the authority to act on problems.

- Map the process: List every step of the process (or each component of the product) in sequence. For each step or part, ask “how could this fail?” and write down all plausible failure modes (e.g. “valve leaks”, “wrong ingredient used”, “solder joint crack”). Be thorough: small issues can cause big trouble later.

- Identify effects and causes: For each failure mode, record its potential effect on the product or process (e.g. “product contaminated” or “machine stops”). Then list possible causes (e.g. “seal worn”, “ingredient mislabeled”, “operator error”). At this point, also note any existing controls (checks or safeguards) you have.

- Rate severity, occurrence, detection: Give each effect a Severity score (1–10, with 10 being most severe to the customer or end use) and each cause an Occurrence score (1–10, 10 being very likely). Also score how hard it is to detect the failure before it reaches the customer (Detection score, 1–10). (These ratings can be based on experience, past data, or simple consensus.) This quantifies each risk.

- Calculate RPN and prioritize: Multiply S × O × D to get the Risk Priority Number (RPN) for each failure mode. A higher RPN means a more critical issue. Rank the failure modes by RPN so the team can focus on the worst ones first. (For example, a mode with Severity=9, Occurrence=5, Detection=7 has RPN=315.)

- Develop action plans: For the top-ranked failure modes, decide on corrective actions to reduce the risk. Actions might include changing the design, improving a process step, adding a quality check, or giving extra training. Record who will do each action and by when. Update the FMEA form with the planned actions in a column (this keeps responsibility clear).

- Monitor results and update: After actions are taken, reconvene to check their effectiveness. If a fix reduces severity or occurrence, update the scores. Continuously improve the process: treat FMEA as a living document and revise it whenever products or processes change.

Each of these steps is iterative: for example, once corrective actions are implemented and new data appear, the team should loop back through the FMEA to update scores and find any remaining issues.

Click HERE for Industrial Automation, ISO Management Systems (ISO 9001, 45001, 14001, 50001, 22000, Integrated Management Systems etc.), Process Safety (HAZOP Study, LOPA, QRA, HIRA, SIS), Quality Management, Engineering, , Project Management, Lean Six Sigma & Process Improvement Self-paced Training Courses

Example Applications in Different Industries

Because FMEA is so flexible, it’s used across many fields. Here are some small-scale examples:

- Food production: Small bakeries, breweries or snack manufacturers can use FMEA on their production line. For instance, one case study applied FMEA to a potato-chip line: the team listed hazards at each step (mixing, frying, seasoning, packaging) and found critical control points to improve food safety and quality. In general, FMEA complements food safety plans by catching hidden process risks. As one food industry guide notes, FMEA “enhances product safety and quality by revealing hidden risks” that normal checks might miss.

- Electronics manufacturing: A small electronics assembler (like PCB production or gadget assembly) can use FMEA to catch design or assembly flaws early. For example, FMEA might reveal that a certain casing design is prone to cracking, or that a soldering step could overheat components. In fact, an FMEA of a consumer phone assembly could flag a weak casing design before mass production. This means fewer field failures and recalls later.

- Metalworking and fabrication: Small metal shops (machining, laser cutting, welding) benefit from FMEA by spotting defects early. For example, FMEA on a laser-cutting process might identify that a worn focus lens (cause) leads to poor edge quality (effect), prompting preventive maintenance. Industry specialists note that modern processes like 3D laser or waterjet cutting “benefit from FMEA to identify and eliminate potential manufacturing defects at an early stage”. In fact, FMEA in metalworking “helps to avoid manufacturing defects, increase quality and reduce the costs of error correction”.

Each of these examples shows the same core idea: break the work into steps, imagine failures, and fix them on paper before they ruin parts or slow down production. Even without fancy tools, a small team can walk through their process in order and use FMEA to preempt trouble.

Common Challenges and Practical Solutions

Small manufacturers often face particular challenges when doing FMEA. Some typical issues and workarounds are:

- Limited time and resources: Small teams may struggle to allocate staff for FMEA. To manage this, prioritize the highest-risk processes first and keep sessions focused. Use simple methods (even a spreadsheet) and short meetings. As one guide advises, “When resources are limited, … focus on the most critical areas of risk”. In practice, start with just one production line or product, fix the top few issues, and expand from there.

- Data and documentation gaps: Small shops may lack historical defect data. Use whatever information is available: past scrap, customer complaints, or operator experience. Keep the FMEA worksheet simple and standardized. Templates or checklists can help ensure nothing is missed. Using a consistent form also makes it easier to train new team members. For example, using a ready-made FMEA template (like the one shown above) saves setup time and keeps things uniform.

- Getting the right team involved: FMEA works best with diverse input, but small firms may have fewer people. Still, try to involve different perspectives: production operators, a maintenance tech, and someone familiar with quality issues. Even if one person wears multiple hats, sitting together and brainstorming generates better coverage of potential failures. Experts stress fostering open, cross-functional collaboration, because “effective collaboration … ensures a comprehensive approach”.

- Keeping it up-to-date: A big challenge is updating FMEA after the initial effort. If the analysis isn’t revisited, it quickly becomes outdated. To avoid this, build reviews into your routine (e.g. quarterly reviews, or after any change in process or product). One recommendation is to treat FMEA as a “living document”. For instance, update the FMEA whenever you install new equipment or change a material. Using versioned files or simple change logs can help track what’s been updated. Regularly reviewing and revising the FMEA ensures it remains useful.

By anticipating these challenges and applying these practical fixes – focusing analysis, using templates, engaging the team, and scheduling updates – small operations can keep FMEA manageable and effective.

Click HERE for Industrial Automation, ISO Management Systems (ISO 9001, 45001, 14001, 50001, 22000, Integrated Management Systems etc.), Process Safety (HAZOP Study, LOPA, QRA, HIRA, SIS), Quality Management, Engineering, , Project Management, Lean Six Sigma & Process Improvement Self-paced Training Courses

Tips for Maintaining and Updating FMEA Over Time

To get long-term value from FMEA, make it a routine part of your quality efforts:

- Schedule regular reviews: Revisit your FMEA at set intervals (e.g. every 3–6 months) or whenever a process changes. This ensures new failure modes are added and old ones are re-scored with up-to-date data.

- Link to continuous improvement: Integrate FMEA with your normal improvement cycle. For example, track completed action items and verify their effect. After implementing a fix, briefly re-run that section of the FMEA to confirm the risk is lowered. Making FMEA part of management or safety meetings helps keep it alive.

- Use tools and templates: Maintain your FMEA document in a clear format. Whether it’s a spreadsheet, a simple database or specialized software, ensure the team knows where to find and how to update it. As your shop grows, you can start with free tools (like spreadsheet templates) and later move to dedicated FMEA software if needed. Keeping the format consistent makes updates faster.

- Educate and involve people: Train new and existing staff on FMEA basics so they can contribute to reviews. When everyone understands why FMEA matters, they’ll more readily suggest updates (for example, a machine operator might notice a new vibration issue that should be added). Encouraging a culture where identifying failure modes is routine keeps the FMEA current.

Overall, treat FMEA as an evolving guide – not a one-time report. Regularly capturing new failure data and re-evaluating scores will keep your risk analysis accurate. As one authority puts it, “perform regular updates and checks” on your FMEA to ensure it continues to prevent problems.

By following these steps and tips, even a small manufacturer can build an effective FMEA process. It will help you catch problems on paper before they happen on the shop floor – saving time, money, and stress in the long run.

Click HERE for Industrial Automation, ISO Management Systems (ISO 9001, 45001, 14001, 50001, 22000, Integrated Management Systems etc.), Process Safety (HAZOP Study, LOPA, QRA, HIRA, SIS), Quality Management, Engineering, , Project Management, Lean Six Sigma & Process Improvement Self-paced Training Courses