Integrating ISO 45001, ISO 9001 and ISO 14001 through an IMS

ISO 45001, ISO 9001 and ISO 14001 are three internationally recognized management system standards covering occupational health & safety (OHS), quality, and environment, respectively. ISO 9001 specifies requirements for a Quality Management System (QMS) to help organizations consistently meet customer and regulatory requirements and improve customer satisfaction. ISO 14001 specifies requirements for an Environmental Management System (EMS), providing a framework to manage environmental impacts without mandating specific performance outcomes. ISO 45001 (2018) specifies requirements for an Occupational Health & Safety (OH&S) management system, enabling organizations to provide safe and healthy workplaces by preventing work-related injuries and ill health and continually improving OH&S performance.

Each standard applies to any organization that chooses to implement it, regardless of size or sector, with scope and applicability defined by the organization’s products, services and interested parties.

Integrating these three standards in an Integrated Management System (IMS) means structuring processes and documentation so that common elements (contexts, policies, objectives, processes, reviews, etc.) are managed together, rather than in silos. This avoids duplication and allows shared use of resources (e.g. personnel, audits, documents). In practice, an IMS typically combines quality, environmental and OHS management (and sometimes others such as security or energy) into one coherent system. By design, ISO 45001 was developed to align with ISO 9001 and ISO 14001 (all follow ISO’s Annex SL “High-Level Structure”), making integration more straightforward. The sections below discuss each standard’s scope, the benefits of integration, real-world examples, key implementation steps, how the common clauses align, and potential challenges with their solutions.

Purpose and Scope of Each Standard

- ISO 9001 (Quality Management) – Defines requirements for a QMS. An organization uses ISO 9001 to demonstrate it can consistently provide products and services that meet customer, regulatory and its own requirements, and to enhance customer satisfaction. It emphasizes a process-based approach and continual improvement (Plan-Do-Check-Act), focusing on meeting stakeholder needs and increasing efficiency. The 2015 revision increased emphasis on risk-based thinking, customer focus, and leadership involvement.

- ISO 14001 (Environmental Management) – Specifies requirements for an effective EMS. ISO 14001 provides a framework rather than environmental performance targets. It helps organizations identify and manage environmental aspects (e.g. waste, emissions, resource use), comply with legal obligations, and pursue continual improvement of environmental performance. ISO 14001:2015 is applicable to any organization wanting to set up or improve an EMS in line with its environmental policy and obligations. It covers understanding context and interested parties, planning for environmental aspects and compliance, operational controls, monitoring and reporting, and improvement.

- ISO 45001 (Occupational Health & Safety) – Specifies requirements for an OH&S management system, aimed at providing safe and healthy workplaces. It requires organizations to identify hazards, assess and mitigate OH&S risks, comply with legal requirements, and set OH&S objectives. By addressing OH&S from a management system perspective, ISO 45001 seeks to prevent work-related injury and ill health and improve overall OH&S performance. Like ISO 9001/14001, it uses the Annex SL structure, so context, leadership, planning, etc. appear in the same clause sequence. ISO 45001 applies to any organization regardless of size or sector that wants to establish, implement and improve an OH&S management system.

Each standard is voluntary and certifiable; many organizations obtain third-party certification to one or more of these. When managed separately, each standard often has its own documentation, audits and processes. An IMS approach integrates these into a single coherent system, leveraging their common structure to save effort and improve consistency.

Click HERE for ISO Management Systems (ISO 9001, 45001, 14001, 50001, 22000, Integrated Management Systems etc.), Process Safety (HAZOP Study, LOPA, QRA, HIRA, SIS), Quality Management, Engineering, , Project Management, Lean Six Sigma & Process Improvement Self-paced Training Courses

Benefits of Integration

Integrating ISO 9001, ISO 14001 and ISO 45001 into one IMS yields many benefits:

- Greater Efficiency and Cost Savings: An IMS eliminates duplicated work. For example, policies, processes (like audit and corrective action) and training can be done once for all three standards rather than three times. “An IMS can benefit your organization through increased efficiency and effectiveness, and cost reductions”. Integrated certification audits (one audit covering all standards) lower certification costs and audit fatigue.

- Consistent Objectives and Processes: An IMS provides a unified framework, so goals (quality, environmental, OHS objectives) and processes are aligned. Consistent terminology, policies and methods across QMS/EMS/OHSMS increase clarity and reduce confusion. Managers gain a “more complete view of the functional needs” and make faster, coordinated decisions.

- Streamlined Compliance and Risk Management: A single system simplifies meeting legal and customer requirements for quality, environmental, and safety issues. By embedding risk-based thinking from all angles, IMS bolsters overall risk management. Integrated incident response and emergency planning (e.g. unified response to accidents) improve resilience. Compliance is easier because one framework covers all relevant laws and regulations. For example, the IMS “simplifies compliance by aligning multiple requirements into a single framework, reducing the risk of non-conformance”.

- Improved Performance and Continuous Improvement: Integrating systems encourages sharing best practices. Red Ambiental (Mexico) found that integrating their QMS, EMS and OHSMS led to “more efficient use of resources, greater profitability, and the elimination of duplicated efforts”. The business saw “reduced operational costs and improved the effectiveness of the management system.” Employees become more engaged: staff buy-in grew as a “core IMS culture” emphasizing quality, safety and sustainability. Organizations gain better data and metrics: a unified system can collect KPIs across quality, environment and safety, enabling broader analysis and strategic planning.

- Easier Audits and Reviews: With common clauses aligned, internal and external audits can be performed together, saving time. For instance, a single internal auditor can audit all processes under one integrated audit schedule. Management Reviews also become consolidated, giving top management a holistic view of performance.

In summary, an IMS leverages the commonalities in ISO 9001/14001/45001 to eliminate redundancies and foster a unified approach. Real organizations report cost reductions, fewer audit days, improved culture and competitive advantage from IMS certification.

Click HERE for ISO Management Systems (ISO 9001, 45001, 14001, 50001, 22000, Integrated Management Systems etc.), Process Safety (HAZOP Study, LOPA, QRA, HIRA, SIS), Quality Management, Engineering, , Project Management, Lean Six Sigma & Process Improvement Self-paced Training Courses

Steps and Considerations in Implementing an IMS

Building an IMS that covers ISO 9001, ISO 14001 and ISO 45001 typically follows a systematic approach. Key steps include:

- Define Scope and Gather Context: Determine the boundaries of the IMS (which sites, products, services) and identify all applicable statutory, regulatory and stakeholder requirements for quality, environment and safety. Understand the organization’s context (Clause 4 of all standards) – internal issues (structure, culture) and external issues (market, regulations, climate factors) – across all disciplines. A unified context analysis helps identify overlaps early.

- Gap Analysis: Assess current systems against the requirements of each standard. Identify existing processes that satisfy requirements in common (e.g. document control, management review, incident investigation) and pinpoint gaps.

- Leadership and Policy: Secure Top Management buy-in. Update leadership structure and responsibilities to cover all areas. Often the organization will create a single integrated policy (Quality + Environment + Safety combined) approved by top management. The management commitment clause (5.1) is shared, requiring active leadership involvement in all three domains.

- Planning Integrated System: Develop a project plan for integration. Identify common elements to unify – for example, consolidate separate quality, environment and safety manuals into one IMS manual; use one set of objectives instead of three lists. Define IMS-wide objectives (covering quality, environmental impacts, OH&S goals) and targets. Use Annex SL structure to align tasks – e.g. a single risk/opportunity register that records quality risks, environmental impacts and safety hazards in one place. Integrate objectives by embedding (for example) environmental targets into the IMS planning process just as quality objectives are set.

- Unified Documentation: Create or revise procedures to serve all standards. For example, a single procedure can govern document control, internal audits and corrective actions for all clauses. (Integrated-Standards notes that “no need to repeat” common requirements.) Digitized document management systems often ease this. Align the management review process so one report covers all requirements (quality, environmental and OHS performance).

- Resource and Training: Allocate resources (staff, budget, IT) to support the IMS. Train all employees on the IMS as a whole. Awareness sessions should cover how individual roles impact quality, environment and safety collectively.

- Implementation of Integrated Processes: Roll out the integrated processes across the organization. Ensure that operations (Clause 8) incorporate all relevant controls – for example, production processes must meet quality criteria and any environmental or safety controls at once. Often organizations start with one function or site (pilot) and extend gradually.

- Monitoring and Internal Auditing: Carry out internal audits against the IMS. You can have integrated audits covering all standards in one visit. For instance, one auditor can check that the integrated process for equipment maintenance meets quality specifications, environmental safeguards (waste oil handling) and safety procedures. This consolidation saves time. Likewise, integrate management reviews into a single annual review.

- Continuous Improvement: Use a unified approach to corrective actions and PDCA. Findings from any audit (quality defect, environmental incident, safety accident) should all feed into the IMS improvement process. Organizations often find new opportunities for improvement that touch multiple areas (e.g. upgrading a process to reduce defects may also reduce waste). Regularly review and update the IMS to incorporate changes in all three domains.

Throughout, consider the High-Level Structure (Annex SL). All ISO management standards use the same clause sequence (Scope, Normative refs, Terms, Context, Leadership, Planning, Support, Operation, Performance Evaluation, Improvement). This means you can unify clauses 4–10 in the IMS. For example, clause 4 “Context of the Organization” is dealt with once for all standards, clause 5 “Leadership” is common, and so on. Only clauses 6 (Planning) and 8 (Operations) carry standard-specific content: for ISO 9001 these focus on product/service realization, for ISO 14001 on environmental aspects, for ISO 45001 on hazard identification.

In practice this allows you to write one context analysis, one leadership commitment section, one procedure for performance evaluation, etc., and then append separate details where needed for each standard’s unique requirements. The specifics of each standard are concentrated on clauses 6 and 8”. In short, take advantage of these overlaps when designing the IMS.

Click HERE for ISO Management Systems (ISO 9001, 45001, 14001, 50001, 22000, Integrated Management Systems etc.), Process Safety (HAZOP Study, LOPA, QRA, HIRA, SIS), Quality Management, Engineering, , Project Management, Lean Six Sigma & Process Improvement Self-paced Training Courses

Aligning Common Elements under Annex SL

Because ISO 9001, 14001 and 45001 share the Annex SL structure, their common elements align naturally:

- Context of the Organization (Clause 4): All three require understanding internal/external issues and interested parties. An IMS analyses these together – e.g. company strategy, market and regulatory issues affecting quality, environment and safety are reviewed in one context assessment. This comprehensive context can reveal interactions (e.g. an environmental regulation also impacts process quality or worker safety).

- Leadership (Clause 5): Top management must commit to each system. In an IMS, leadership involvement is unified. A single policy may cover quality, environment and safety commitments. Management assigns roles and responsibilities for the IMS holistically.

- Planning (Clause 6): In all standards, organizations identify risks and opportunities and set objectives. An IMS combines risk/opportunity registers and objective setting. For example, a risk assessment might identify that poor maintenance could cause both product defects and worker injuries; the IMS plan would then assign a corrective project that addresses both quality and safety. Objectives can be aggregated (e.g. a single objective to “improve process efficiency by X%” can include sub-objectives for defect rate, waste reduction, and incident reduction).

- Support (Clause 7): Resources, competence, communication and documented information requirements are the same structure. Organizations can implement one integrated document control system, one set of training programs and one internal communication system. For instance, training on “operational procedures” teaches both quality steps and safe practices together. All standards require worker participation or awareness – an IMS ensures people are aware of combined QMS/EMS/OHSMS requirements.

- Operation (Clause 8): This clause differs by standard: ISO 9001 focuses on product/service realization, ISO 14001 on controlling environmental aspects, ISO 45001 on controlling health and safety hazards. In an IMS, operational controls are documented in an integrated way. For example, a manufacturing procedure will be written to include quality checkpoints, environmental controls (e.g. spill prevention) and safety steps (e.g. lockout/tagout). Integrated-Standards notes that “similar processes are seamlessly managed and executed without duplication” in an IMS.

- Performance Evaluation (Clause 9): All systems require monitoring, measurement, analysis, internal audit and management review. An IMS uses one combined audit program and one combined management review meeting. Performance data (KPIs) for quality, environment and safety are presented together. As KTL points out, an IMS “provides clear methods and processes to identify and prioritize risks, set and monitor goals, [and] communicate risks to employees and management” across all disciplines. This gives management a unified dashboard of performance.

- Improvement (Clause 10): Continual improvement, corrective actions and preventive (risk treatment) actions are managed collectively. One corrective-action procedure handles nonconformities whether they come from a quality defect, an environmental spill or a near-miss incident. Improvement initiatives often have multi-faceted benefits in an IMS (for example, a new waste recycling program might improve environmental performance and also raise employee engagement in overall sustainability goals).

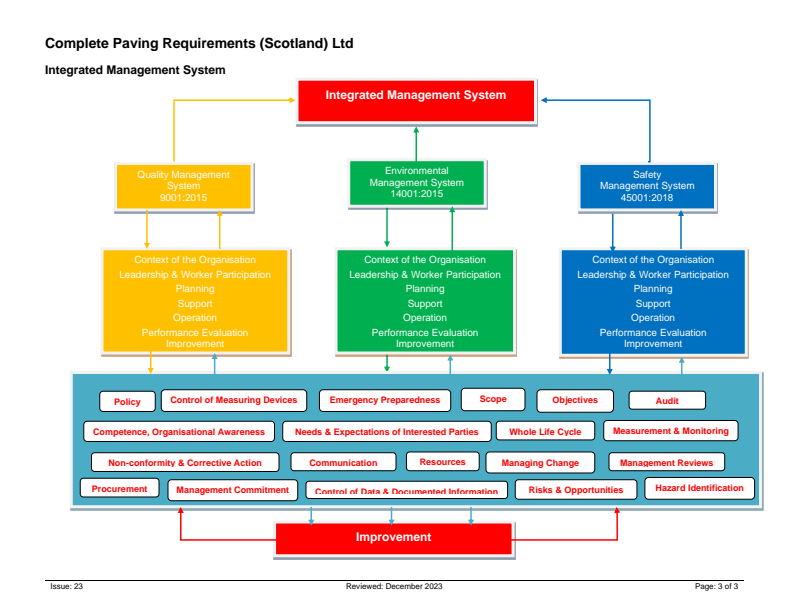

The diagram above illustrates an IMS framework. It shows ISO 9001 (yellow), ISO 14001 (green) and ISO 45001 (blue) requirements feeding into a central Integrated Management System. The common elements (center grey box) – context, planning, support, operation, performance evaluation and leadership – are shared across all three systems. This unified Plan–Do–Check–Act cycle ensures each standard’s requirements contribute to a single continuous-improvement loop. (Image source: Complete Paving Requirements Ltd IMS Manual.)In summary, because of Annex SL, organizations can implement one IMS process for clauses 4,5,7,9,10 and only tailor clauses 6 and 8 to each standard’s specifics. This common high-level structure is what makes ISO 45001, 9001 and 14001 integration practical.

In summary, because of Annex SL, organizations can implement one IMS process for clauses 4,5,7,9,10 and only tailor clauses 6 and 8 to each standard’s specifics. This common high-level structure is what makes ISO 45001, 9001 and 14001 integration practical.

Click HERE for ISO Management Systems (ISO 9001, 45001, 14001, 50001, 22000, Integrated Management Systems etc.), Process Safety (HAZOP Study, LOPA, QRA, HIRA, SIS), Quality Management, Engineering, , Project Management, Lean Six Sigma & Process Improvement Self-paced Training Courses

Challenges and How to Overcome Them

While the benefits of an IMS are clear, integration also presents challenges:

- Complexity and Change Management: Merging separate systems can be complex. Departments used to working in silos (e.g. Quality vs. HSE) may resist changing their procedures. Employees may fear extra workload or loss of autonomy. For example, aligning the risk-based thinking of ISO 9001 with the life-cycle perspective of ISO 14001 can be difficult. To overcome this, robust planning and communication are needed. Start with a thorough gap analysis and clear implementation plan. Engaging stakeholders early (through workshops or cross-functional teams) builds buy-in. Leadership must champion the IMS, emphasizing the strategic benefits and providing resources. Training is essential: ensure everyone understands the integrated approach and how it helps their work, not hinders it.

- Documentation Overload: Combining three standards means a lot of documented information. Developing, syncing and maintaining integrated procedures can be daunting. It’s easy to fall into simply appending three manuals together. The solution is to streamline documentation: create one set of documents for all common clauses and only branch out where necessary. Use digital document management to reduce clutter. Templates and IMS toolkit guides (e.g. ISO’s Guide 83 on integrating standards) help map clauses together. Regularly review documents to remove redundancies.

- Resource Constraints: Especially for SMEs, dedicating time and money to an IMS can be challenging. Integration projects require skilled personnel or consultants. To mitigate this, take a phased approach: begin with the standards you have and gradually include others. Leverage what exists (e.g. if you already have ISO 9001, layer in ISO 45001 and 14001 gradually). Use affordable tools or IMS software that automate compliance tasks and record-keeping.

- Cultural and Structural Silos: If organizational culture is fragmented, integration suffers. Departments may prioritize their own standards (e.g. safety team vs quality team). Breaking down silos requires building an IMS culture: create cross-functional IMS committees or champions from each area to ensure balanced input. Adopt one unified policy and vision: for instance, a single mission statement committing to “excellence in quality, environment and safety” sets a shared goal.

- Auditing and Certification Hurdles: Finding auditors or registrars experienced in integrated audits can be tricky. Some auditors may try to audit clauses in isolation rather than holistically. To address this, choose certification bodies with IMS expertise. Prepare your auditor by explaining your IMS structure in advance so they audit the system cohesively.

Despite these challenges, many organizations successfully overcome them through strategic planning and continuous improvement. Key enablers include strong top management commitment and a clear project plan. Regular communication, training and demonstration of quick wins help sustain momentum. By addressing issues like documentation and culture upfront, organizations can transition smoothly.

Conclusion

Integrating ISO 9001, ISO 14001 and ISO 45001 into an IMS is a powerful approach for compliance managers and business leaders seeking efficiency and coherence in management systems. Each standard brings a valuable focus (quality, environment, safety), and the common Annex SL structure means they can be implemented together with reduced duplication. Benefits include streamlined processes, lower audit costs, unified objectives, improved risk management, and strengthened organizational culture. Successful implementations show that careful planning, leadership support, and employee involvement are critical. Key steps include defining scope, conducting a gap analysis, aligning policies and procedures, and leveraging common processes for training, auditing and review. While challenges like complexity and documentation exist, they can be managed through a phased, well-communicated approach.

In summary, an IMS aligning ISO 9001, 14001 and 45001 helps organizations “work as a single unit” towards their goals. By taking advantage of the shared HLS framework, companies can achieve consistent, resilient operations that simultaneously assure product quality, minimize environmental impact, and protect employee health and safety. As ISO itself notes, this integrated approach optimizes efficiency, ensures regulatory compliance, and fosters continual improvement across all areas of performance.

Click HERE for ISO Management Systems (ISO 9001, 45001, 14001, 50001, 22000, Integrated Management Systems etc.), Process Safety (HAZOP Study, LOPA, QRA, HIRA, SIS), Quality Management, Engineering, , Project Management, Lean Six Sigma & Process Improvement Self-paced Training Courses

- Integrated Management Systems (IMS) Implementation Masterclass

- Integrated ISO Management Systems (IMS) Audit – Best Practices

- ISO 19011: Auditing Management Systems – Techniques & Best Practices

- ISO 9001 Quality Management Systems Lead Auditor

- ISO 14001 Environmental Management Systems Lead Auditor

- ISO 45001 Occupational Health & Safety Lead Auditor

- ISO 50001 Energy Management Systems Lead Auditor

- Food Safety Management Systems (FSMS) Implementation

- ISO 22000 Food Safety Management Systems Lead Auditor

- FSSC 22000 Lead Auditor (Food Safety)

- ISO/IEC 17025 Laboratory Management Systems (LMS) Certification

- Laboratory Management Systems (LMS) Essentials

- Lean Six Sigma Yellow Belt Certification Course

- Lean Six Sigma Green Belt Certification

- Lean Six Sigma Black Belt Certification

- Lean Manufacturing Certification Course

- Six Sigma for Manufacturing & Operational Efficiency

- Statistical Process Control (SPC) Training Course

- Measurement Systems Analysis (MSA) Training Course

- Strategic Supply Chain Management Training Course

- Operational Risk Management Training Course

- Quality Management Training Course

- Health, Safety and Environment (HSE) Training Course

- Industrial Process Automation Training Course

- Advanced Digital Manufacturing & Product Design Technologies Training Courses

- Advanced Digital Manufacturing & Product Design Technologies Training Courses

- Safety Instrumented System

- Hazards and Operability Study (HAZOP)

- Layer of Protection Analysis (LOPA)

- Quantitative Risk Assessment (QRA)

- Process Safety Management (PSM)

- Industrial Process Safety