ISO 9001 Quality Management Systems and the PDCA Model

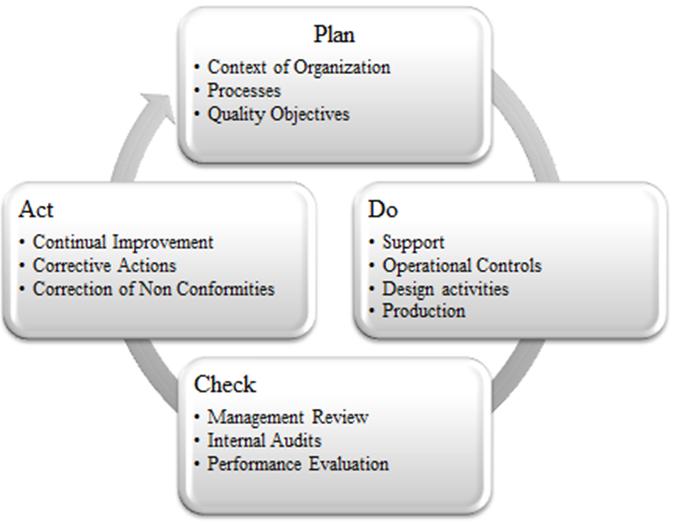

The Plan-Do-Check-Act (PDCA) model is a cyclic process conceptualized by Walter Shewhart and widely promoted by Edward Deming. The two are referred to as the founders of most of the quality philosophies that are widely in use today.

The PDCA concept is simply a cycle for effecting change which, when implemented and repeated, would yield repeated improvements in any process. It is an iterative four-step managing technique utilized in industry for the continuous improvement of their processes.

Click Here to Join the Over 2,600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 2,600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Phases of the PDCA Model

- Plan

This phase involves the establishment of the objectives and processes essential to provide outcomes that are in line with needed output. It include planning on how to realize the product or service, including what resources are required and how they will be used, is the last step in the early planning.

- Do

In this phase, the execution of the plan, performance of the process, and/or production is carried out. It is at this stage that, an organization gathers process statistics for recording and examination in the next steps of Check & Act. This stage includes sourcing and purchasing raw materials against requirements, monitoring, testing and validating processes etc.

- Check

This stage involves examining the actual results of the ‘Do’ phase, and assessing it against the expected results of the plan phase. It is mandatory to check and measure not merely the product to make sure it fulfils requirements, but to also assess and measure the processes as well. The check phase includes the following: analysis of process data, internal /external audits and management review.

- Act

If the check phase of the PDCA cycle reveals that the Plan applied in the Do phase is a progressive improvement to the earlier results, the present ‘Do’ then becomes the new standard for how the organization should ‘Act’ going forward. However, if the result of the check phase analysis reveals that the Plan applied in Do phase is not an improvement, then the prior standard remain.

In both cases, more understanding of the process is needed which will serve as a basis for the next PDCA cycle. Corrective actions and action plans that resulted from output of management review meetings and internal audits acts as part of the Act phase of PDCA cycle.

Click Here to Join the Over 2,600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 2,600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

When to Use PDCA Model

PDCA cycle can be used under the following circumstances:

- When initiating a new improvement project.

- When opting for continuous improvement.

- When modifying or designing a new part of a process, product or service.

- When defining a repetitive work process.

- When collating or analysing data so as to verify and prioritize problems or root causes.

- When applying any change.

Click Here to Download Readymade Editable Tools & Templates on Quality Assurance/Quality Control, RCA, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, HSSE, Project Management etc.

Click Here to Download Readymade Editable Tools & Templates on Quality Assurance/Quality Control, RCA, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, HSSE, Project Management etc.

PDCA Cycle and ISO 9001

The PDCA model is an integral part of ISO 9001 Quality Management System. It is embedded into the standard. Organizations opting for ISO 9001 automatically adopts PDCA cycle.

- Plan

Planning is a major part of the quality management system which begins with realizing the context of the organization and the expectations of interested parties, captured at Clauses 4.1 & 4.2 of ISO 9001 standard, and then utilized to define QMS scope and processes according to Clauses 4.3 & 4.4 standard.

Then commitment of leadership in the company guides the organization to a customer focus by outlining organizational roles and responsibilities and by instituting a quality policy to focus on QMS according to Clauses 5.1, 5.2 & 5.3 of ISO 9001 standard.

Planning also helps identify and address the risks and opportunities of the quality management systems. The planning includes setting and planning for quality objectives and changes to support continual improvement as outlined at Clauses 6.1, 6.2 & 6.3 ISO 9001 standard.

The final layer of planning involves recognizing and defining the support structure to perform the plans, which includes the resources (Clause 7.1), recognizing competence (Clause 7.2), awareness (Clause 7.3), communication (Clause 7.4) and to have the system for creation and control of documented information (Clause 7.5).

Click Here to Download Readymade Editable Tools & Templates on Quality Assurance/Quality Control, RCA, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, HSSE, Project Management etc.

Click Here to Download Readymade Editable Tools & Templates on Quality Assurance/Quality Control, RCA, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, HSSE, Project Management etc.

- Do

An unimplemented plan only remains a plan. Plans are meant to be implemented. While implementing the plans, Controls need to be put in place for the operations, product or service requirements (clause 8.2). For designs to be developed (clause 8.3), controls needs to be placed on external providers according to clause 8.4. The course of producing the product or service needs to be applied with control of product and service release according to clause 8.5 & 8.6, and non-conformities in the course of running the operations needs to be addressed as outlined at clause 8.7 of ISO 9001 standard.

- Check

There are numerous places in the standard to check the effectiveness of the quality management system. The ISO standard requires enterprises to monitor, measure, analyze and evaluate the products or services to make sure that the processes employed are satisfactory and effective, and that customer satisfaction is achieved as outline at Clause 9.1 of ISO 9001 standard. Internal audits according to Clause 9.2, acts as a means for measuring the effectiveness of the quality management system. The Management Review procedure as stated at Clause 9.3 of ISO 9001 standard is aimed at analysing and evaluating all the collected information related to the quality management system and helps to identify solutions to resolve any issues or problems.

Click Here to Join the Over 2,600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 2,600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

- Act

This phase of ISO 9001 quality management systems includes the required actions to address any concerns revealed at the check phase. Improvement according to Clauses 10.1 & 10.3 of ISO 9001 is the main purpose for these action items outlined at Clause 10.1 of the standard. This action occurs when removing nonconformity and taking Corrective Actions according to Clause 10.2 of the standard in order to eradicate the reasons for current and foreseeable nonconformities.

At the end of the “Act” phase, some changes are likely to surface at the initial “Plan” of the quality management system; this then marks the beginning of the cycle again. As already stated, the cycle is a repetitive one.

Click Here to Join the Over 2,600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 2,600 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

About the Author

Adebayo is a thought leader in continuous process improvement and manufacturing excellence. He is a Certified Six Sigma Master Black Belt (CSSMBB), Digital Manufacturing Professional and ISO Management Systems Lead Auditor (ISO 9001, 45001 & ISO 22000) with strong experience leading various continuous improvement initiative in top manufacturing organizations.

You can reach him here.