Optimizing Production Flow: A Comprehensive Guide to Line Balancing

Line balancing is the process of assigning tasks to workstations so that each station has roughly the same total work time, matching the production rate (takt time) to demand. In practice this means breaking the overall production process into elemental tasks, charting their precedence relationships, and distributing them among workstations so that no station becomes a bottleneck or has excessive idle time. A well-balanced line aligns operator and machine workload with customer demand, creating a smooth flow of material. This minimizes waiting and handling, ensuring that each product moves steadily through the assembly with minimal interruptions.

By eliminating bottlenecks, line balancing greatly improves overall manufacturing efficiency. It is a core lean production strategy (often known by Toyota’s term heijunka) for leveling production, reducing unevenness, and eliminating waste. In effect, line balancing ties manpower and machine capacity precisely to takt time (the cycle time required to meet demand). This synchronization prevents the buildup of work-in-process inventory and ensures consistent output: if one station slows down, it would impede the entire line’s throughput.

Objectives and Benefits of Effective Balancing

The primary objective of line balancing is to maximize throughput while minimizing idle time and waste. An effectively balanced line achieves this by:

- Minimizing Idle Time: By distributing tasks so that each workstation’s processing time is close to the cycle time, no station sits idle while others work. This reduces waiting waste and unutilized capacity.

- Smoothing Material Flow: A balanced workflow means work moves continuously from one station to the next at the desired pace. This streamlined flow reduces delays and stabilizes production. (Unbalanced lines often cause “bunching” or starvation of parts.).

- Higher Output and Utilization: With fewer bottlenecks and downtime, the line produces more units in the same time. All available labor and equipment are used effectively, raising the line’s capacity and the factory’s productivity.

- Reduced Wastes and Costs: Balanced lines generate less overproduction and excess inventory. By matching production closely to demand, manufacturers avoid inventory waste and unnecessary labor costs. For example, studies show that balancing an assembly line can significantly cut the number of machines or operators needed while increasing output.

- Improved Quality and Morale: Consistent, balanced work reduces stress on operators and machines, often leading to higher quality (fewer rushed processes) and better employee morale. Workers in a well-balanced line are neither overworked nor idle, which encourages teamwork and continuous improvement.

In short, line balancing aligns every part of the production system — tasks, operators, machines, and takt time — so that the process meets demand smoothly. When done well, it boosts throughput, lowers lead time, cuts costs, and supports lean manufacturing goals.

Click Here to Download Readymade Lean Manufacturing, Six Sigma, Lean Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, HACCP, Food Safety & Integrated Management Systems (IMS) Templates.

Challenges in Achieving Balance

Several practical challenges make line balancing difficult. First, variability in demand and product mix means the ideal workload per station can change rapidly. In many factories, customer orders fluctuate or new products are introduced frequently. Adapting to these changes requires a flexible line design (e.g. quick changeovers and cross-trained staff) or the line will quickly become unbalanced.

Second, task dependencies and precedence constraints restrict how tasks can be grouped. Some operations cannot start until others finish (for example, you must attach brackets before installing motors). Complex precedence requirements limit the ways tasks can be split among stations. This makes it hard to equalize workloads, especially if some tasks are very long or cannot be subdivided further.

Third, equipment and human variability can upset even a planned balance. Machines may run at different speeds or break down, and operators have different skill levels. Unplanned downtime or quality problems at one station will force idle time elsewhere. Likewise, poor line design (for example, too many tasks assigned arbitrarily) or overscheduling can create excess idle time or bottlenecks.

In practice, many lines must be periodically rebalanced. Lean experts note that whenever demand shifts — such as moving to a new product model or seasonal changes — the line often needs adjustment, sometimes as frequently as every shift. Without continual review and adjustment, even a perfectly balanced line will drift out of balance, wasting capacity and creating variability.

Key Techniques and Methods

Engineers use a mix of analytic and heuristic techniques to tackle the line-balancing problem. One of the first steps is to diagram all tasks and dependencies. A precedence diagram (or task dependency chart) lists every work element and shows which tasks must precede others. This clarifies the allowable assignments (you cannot place a task before its prerequisites) and is the starting point for any balancing effort.

From there, common methods include:

- Heuristic Rules: Simple rule-based approaches assign tasks in priority order. For example, the Largest-Candidate Rule (LCR) sorts tasks by processing time and assigns the largest tasks first to stations, filling each station up to the cycle-time limit. The Ranked Positional Weight (RPW) method assigns each task a “positional weight” (the task’s own time plus times of all successors) and then schedules the highest-weight tasks first. The Kilbridge & Wester method is another classic: it identifies the critical path (longest chain of tasks) and iteratively adjusts cycle times to balance that path across stations. These heuristics do not guarantee an optimal solution, but they are intuitive and often produce good results quickly.

- Computerized Optimization: Especially for complex lines or large numbers of tasks, software tools can automate the balancing. Modern systems can take task times and constraints as input and use algorithms (or even AI/ML) to find near-optimal assignments. In practice, engineers may build a digital simulation model of the line: they input all tasks, workers, and machines, then let the software identify bottlenecks or imbalance. The software can then adjust task assignments, re-simulate under different demand scenarios, and recommend changes. This “what-if” capability is powerful for evaluating alternative layouts before making changes on the factory floor.

- Work-Element Allocation: In lines with very long tasks, one may break down tasks or add parallel workers. For instance, if one operation takes 4 minutes but takt time is 1 minute, engineers might assign four people to that station or split the task into subtasks at multiple stations. Conversely, very short tasks might be combined into one station to avoid fragmentation. Judicious splitting/combining of tasks is part of the iterative balancing process.

In practice, a balanced line is usually achieved by applying a mix of these methods: engineers may try a heuristic assignment and then refine it using simulation or manual adjustments. The goal is always the same: make each station’s total time about equal to the cycle time (demand rate) without violating any task order constraints.

Click Here to Download Readymade Lean Manufacturing, Six Sigma, Lean Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, HACCP, Food Safety & Integrated Management Systems (IMS) Templates.

Metrics for Line-Balance Efficiency

Line balance is evaluated by how little idle time the line has. Two common metrics are balance delay (also called balance loss) and line efficiency.

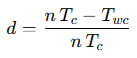

- Balance Delay (d): This measures the fraction of time that workstations are idle due to imbalance. It is usually expressed as a percentage or fraction:

where n is the number of stations, T_c is the cycle time (seconds per unit), and Twc is the total work content (sum of all task times). Intuitively, nTc is the total time available across all stations in one cycle, while Twc is the time actually needed. A perfectly balanced line has d=0, meaning zero idle time. A higher delay indicates more idle time and inefficiency.

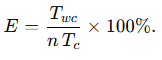

- Line Efficiency: Often reported as a percentage, this is essentially the complement of delay. One way to compute it is:

In other words, E = (sum of task times) / (number of stations × cycle time)【9†】. If the tasks perfectly fill all station times, E = 100%. In practice, line efficiency is typically less than 100% because some idle time is unavoidable. Tracking efficiency and delay together gives a full picture: for example, a balance delay of 12.5% means an efficiency of 87.5%.

Other performance indicators are also used. Takt time adherence measures how well the line maintains the target cycle time (i.e. producing exactly the required output per period). Throughput rate (units per hour) and work-in-progress (WIP) levels are also monitored. Managers often track OEE (overall equipment effectiveness) as well, but for pure balancing the focus is on how closely production rate matches demand with minimal waste.

Tools and Software

In modern manufacturing, many digital tools support line balancing. At a basic level, engineers use spreadsheets, charts, and time-study data to do the calculations. More advanced factories leverage specialized software: for example, many ERP/MES systems include a line-balancing module that can automatically compute station assignments and simulate changes. One cited ERP (IFS) even promises automated balancing based on preset parameters.

Similarly, discrete-event simulation packages (such as Arena, Simul8, Witness or FlexSim) are often used to model and test an assembly line virtually. These tools let engineers input task times, routing logic, and resource constraints, then run “virtual production” to identify bottlenecks. The software can then reassign tasks or add resources and re-run the simulation to compare outcomes. Simulation makes it easy to test what-if scenarios (different demand patterns, machine speeds, etc.) before physical implementation.

There are also dedicated line-balancing programs (offered by companies like Proplanner, AVIX, and others) that combine task assignment with visual scheduling. Some emerging solutions even apply AI or optimization algorithms to find near-optimal assignments quickly. In any case, the goal of these tools is the same: accelerate the balancing calculations and handle large numbers of tasks with complex constraints. As one source notes, “computerized line balancing” uses data collection, modeling, and optimization to balance the production process more efficiently than manual methods.

Click Here to Download Readymade Lean Manufacturing, Six Sigma, Lean Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, HACCP, Food Safety & Integrated Management Systems (IMS) Templates.

Steps in the Line-Balancing Process

Achieving a balanced line is usually done in a series of logical steps. A typical workflow is:

- List tasks and draw a precedence diagram. Break down the product assembly into all individual work elements and record the time for each (from time studies). Draw a diagram showing which tasks precede others, so you know what sequences are allowed.

- Determine cycle time and station count. Based on demand, compute the takt time (cycle time) required to meet customer rate. From the task times, calculate the total work content Twc (sum of all tasks). Then estimate the theoretical minimum number of stations as n = Twc / Tc (rounding up). This gives a target for how many stations (or operators) you will need.

- Assign tasks to stations. Starting with the first station, assign tasks from the precedence list while keeping the total at or below the cycle time. Continue station by station, always respecting the task order and trying to equalize the times. Heuristics are often used here (e.g. largest tasks first). Keep adjusting which tasks go to which station until no station’s total significantly exceeds others.

- Adjust for bottlenecks and takt. If some station is overloaded, consider splitting tasks or adding resources (e.g. two people at that station). If a station has too little work, you might combine its tasks with another. Reassign workers (or machines) as needed. At every step, compute takt time to ensure the line can meet demand: if any station’s time exceeds takt, the line will fall behind.

- Evaluate the line and iterate. Compute the balance delay (idle time) and line efficiency for your assignment. If the delay is still too high, look for ways to rearrange tasks or change the number of stations. In practice, one may test the line on paper or in simulation to catch hidden issues. Balance, measure, and rebalance until the performance metrics (throughput, delay) are satisfactory.

Throughout these steps, continual refinement is key. Often the first solution is not ideal, so engineers will shuffle tasks, re-calculate, or even modify task definitions (split or combine tasks) until a workable balance is found.

Best Practices and Real-World Implications

In real manufacturing environments, successful line balancing is a dynamic, ongoing process. Lean manufacturing practices emphasize flexibility and continuous improvement. For example, Toyota supervisors regularly adjust headcount on the line so that labor exactly matches takt time, preventing both under- and over-staffing. This is part of heijunka (production leveling) in the Toyota Production System. As experts note, an imbalanced line quickly creates waste (excess WIP and idle operators) which contradicts lean flow goals.

- Plan for flexibility: Real lines should be designed with changeover in mind. Best practice is to cross-train workers so they can move to different tasks as demand shifts, and to implement quick-changeover techniques (SMED) so the mix of products on the line can be changed rapidly. Standardized work procedures and visual controls also help – if a line starts to drift, operators should see the imbalance immediately (e.g. via andon lights or balance charts) and take corrective action.

- Integrate with lean/continuous improvement: Line balancing does not happen in isolation. As workers eliminate waste from their processes (through Kaizen events), the line can become unbalanced (new idle time appears). In the Toyota approach, any idle time freed by improvement is immediately redeployed to other value-added work or continuous improvement tasks. In other words, line balancing actualizes the gains: rather than leaving operators idle after a Kaizen, they are shifted to other stations or new tasks, so the line’s performance continues to improve.

- Use data and iteration: Good balance requires good data. Times for tasks should be based on accurate time studies or historical cycle-time data. Many companies use digital tools or MES dashboards to collect real-time throughput and cycle-time information. This data can trigger rebalancing when, for example, one station falls behind its target. Continuous monitoring of key metrics (throughput, balance delay, WIP) helps managers spot when the line balance is no longer optimal and needs adjustment.

Click Here to Download Readymade Lean Manufacturing, Six Sigma, Lean Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, HACCP, Food Safety & Integrated Management Systems (IMS) Templates.

Real-world outcomes

Well-executed line balancing delivers substantial benefits. Industry reports note that balancing an automotive or appliance line can increase capacity by double-digit percentages without adding equipment. Conversely, poor balancing often leads to hidden capacity – machines or people sitting idle while others struggle – which is costly. In lean terms, balancing is a way to unlock hidden capacity on existing lines. For example, one case study showed that a rebalanced line increased output by 14% and raised the production rate from 1,080 units to 1,234 units per day (a 14% gain).

In summary, line balancing is a foundational engineering practice in modern factories. When done systematically – using task analysis, precedence charts, balancing algorithms, and performance metrics – it aligns operations with demand and substantially improves production efficiency and cost-effectiveness. Engineers and managers should view it not as a one-time project but as a continuous discipline, closely tied to lean manufacturing, that maximizes throughput while reducing waste.

Click HERE to download or any of the following documents:

Integrated Management Systems (IMS) Implementation

IATF 16949 Automotive Quality Management Implementation Kit

ISO/IEC 17025 Laboratory Management System Implementation Kit

HACCP Implementation Kit

ISO 9001 Quality Management Systems (QMS) Implementation

ISO 22000 Food Safety Management Systems (FSMS) Implementation

Food Safety Systems Certification (FSSC) 22000 v5 Implementation

ISO 14001 Environmental Management Systems (EMS) Implementation

ISO 45001 Occupational Health & Safety Management Systems (OH&SMS) Implementation

ISO 50001 Energy Management Systems (EnMS) Implementation

Industrial Health, Safety & Environmental Management (HSE) Kit

Process Manuals

SON Compliance Documentation Kit

NAFDAC Compliance Documentation Kit

QA/QC Documentation Kit

Equipment Maintenance Documentation Kit

Production Management Documentation Kit

Production, Quality Control / Equipment Maintenance Kit

Lean Six Sigma

Lean Management/Manufacturing

Six Sigma Kit

Supplier Quality and Compliance Management (SQCM) Kit

Risk Management