Prioritization Matrix for Decision Making & Problem Solving

The prioritization matrix is a powerful tool that can be used in prioritizing tasks or goals based on two key factors namely, importance and urgency. By determining how important and urgent a task is, you can easily prioritize what may need to be done and ensure that you're always working on the most important tasks.

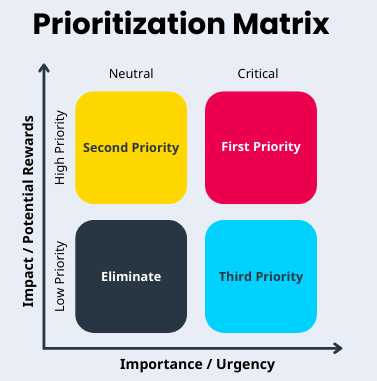

A prioritization matrix is essentially a four-quadrant grid with the x-axis being used to assess the importance or urgency of an issue, and the y-axis used to assess the impact or potential rewards. Basically, the quadrants are used to prioritize the options based on their urgency and importance.

Click Here to Join the Over 2000 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 2000 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Prioritization matrices provide a mechanism for ranking the relative importance of ideas or issues that assists in deciding what to do after key actions or Critical-To-Quality (CTQ) characteristics have been identified but their relative importance is not known with certainty.

It is a visual diagram used to compare multiple (at least two) sets of data using some sets of criteria. The matrix consists of a set of criteria options and the alternatives under consideration.

Prioritization matrices are especially useful if problem-solving resources, such as people, time or money, are limited, or if the identified problem-solving actions or CTQs are strongly interrelated.

Click Here to Download Readymade Editable Toolkits & Templates on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, HSSE, Project Management etc

Click Here to Download Readymade Editable Toolkits & Templates on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, HSSE, Project Management etc

4 Levels of Prioritizing Tasks

There are basically four (4) levels of prioritizing tasks as discussed below. The manner and ways of handling each level vary from one person to another and from one company to another.

- Critical – These are tasks that are considered urgent and time-sensitive, requiring the team to stop whatever they are doing and immediately focus on them. When a critical task is not immediately attended to, it can create various risks for an organization.

- High priority – In terms of time sensitive, high priority tasks are quite similar to critical tasks but are less time sensitive. They can be done in a distant interval, say a week or so, hence it comes second amongst the levels.

- Neutral – This level of task delivery has no immediate deadline, hence can be patiently done.

- Low priority – In this level, a task can be done at any given time. In a case of an already fixed deadline, it can be moved or changed anytime without any problem.

Benefits of Using a Prioritization Matrix

Using a prioritization matrix provides many benefits, including the following:

- Breaking down and prioritizing complex issues: Prioritization Matrix helps in breaking down and prioritizing complex issues, especially when various factors affect decision-making.

- Ranking Priorities: The matrix enables you easily categorize and rank your task priorities.

- Helps Directs your Focus: Identifies the most important areas that need to be focused on

- Team Building: Enables you assembles a team that supports essential buy-ins.

When to Use the Prioritization Matrix

The prioritization matrix should be used when

- You cannot do everything at once,

- You are uncertain about the best use of your resources or energy or

- You are looking toward specific improvement goals.

Steps to Implementing the Prioritization Matrix

The following are some steps for implementing prioritization matrix for your processes:

- Step 1: Agree on the ultimate objective.

- Step 2: List all criteria needed to meet the goal.

- Step 3: Compare relative importance of criterion.

- Step 4: Evaluate your options against weighted criteria.

- Step 5: Evaluate criteria with reference to other criterion.

- Step 6: Compare possible choices for remaining criteria.

- Step 7: Merge the relative ability of a possible choice to deliver a desired criterion with the relative weighting of that criterion.

Click Here to Join the Over 2000 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 2000 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Download a FREE Prioritization Matrix Template Below...

Click Here to Download Readymade Editable Toolkits & Templates on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, HSSE, Project Management etc

Click Here to Download Readymade Editable Toolkits & Templates on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, HSSE, Project Management etc

About the Author

Adebayo is a thought leader in continuous process improvement and manufacturing excellence. He is a Certified Six Sigma Master Black Belt (CSSMBB) Professional and Management Systems Lead Auditor (ISO 9001, 45001, ISO 22000/FSSC 22000 etc.) with strong experience leading various continuous improvement initiative in top manufacturing organizations.

You can reach him here.